Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Bridges are more than just infrastructure; they are vital arteries that connect communities, enable commerce, and support development. Behind the scenes of every successful bridge project lies a rigorous commitment to quality control and structural integrity—especially at the foundation level. One essential tool that made a significant contribution to the recent bridge construction over the Nan River in Nan Province, Thailand, is the Ultrasonic Drilling Monitor (UDM) device—model TS-K100CW.

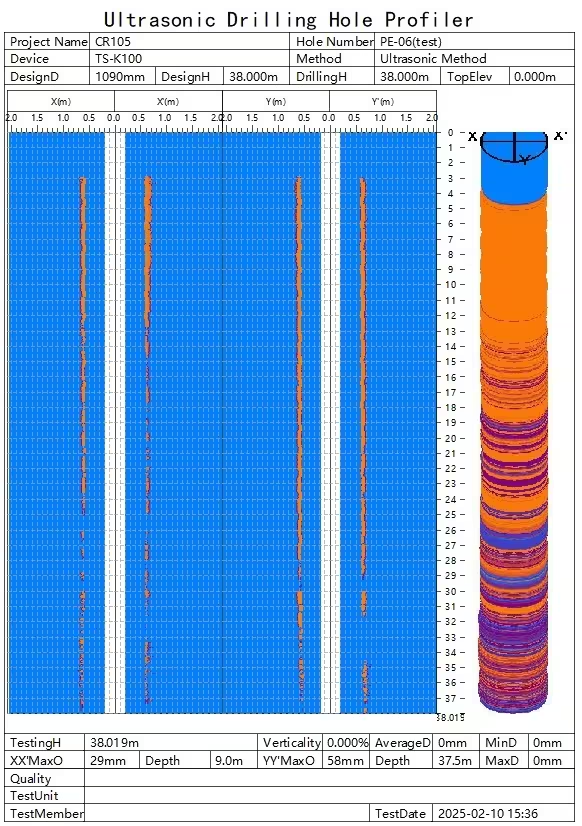

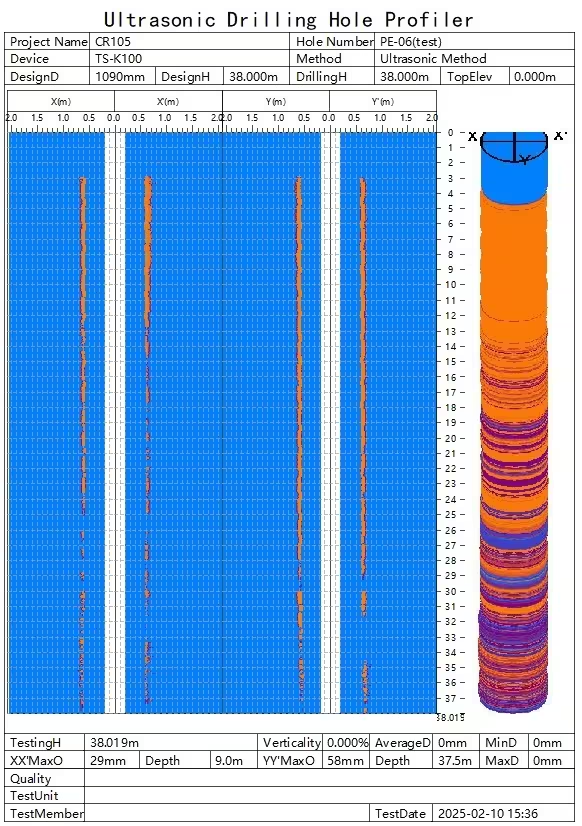

Tensense Geotech UDM device was selected to ensure the highest quality standards in borehole formation before foundation piles were cast. By accurately testing borehole diameter, verticality, and sediment thickness, the device played a critical role in guaranteeing the structural soundness of the bridge’s foundation. Real-world photos and videos captured during the testing process now stand as a testament to our technology’s reliability and efficiency.

Project Overview: A Bridge Over the Nan River

The Nan River bridge project was a landmark infrastructure development aimed at enhancing transportation efficiency in northern Thailand. Located in the scenic and historically rich Nan Province, the project required uncompromising quality, particularly in sub-surface construction.

Given the geotechnical complexity of the region—ranging from water-saturated soils to variable sediment deposits—the engineering team prioritized borehole integrity from the outset. That’s where our UDM device came in.

The UDM Advantage: What Sets the TS-K100CW Apart

The TS-K100CW Ultrasonic Hole and Groove Formation Detector, developed in-house, is a high-precision device purpose-built to ensure borehole quality in various challenging conditions. Here’s how it contributed to the success of the Nan River project:

1. Accurate Borehole Profiling

The UDM device was tasked with detecting and measuring:

These parameters are critical because any deviation or unexpected sediment buildup can compromise the structural load-bearing capacity of drilled piles. The TS-K100CW’s ultrasonic probe, capable of detecting apertures from Ф400mm to Ф8000mm and reaching depths of up to 4000mm, ensured detailed profiling of each borehole.

2. Robust in Challenging Environments

Nan Province’s subsurface conditions include both dry and muddy holes. The UDM device is specifically engineered to operate reliably in such conditions, thanks to:

These capabilities allowed our team to detect and interpret borehole anomalies without disruption, enhancing both accuracy and efficiency on-site.

3. Fully Integrated Testing

One of the TS-K100CW’s standout features is its multifunctional integrated probe. Unlike older methods requiring separate tools and tests for different measurements, this device performed all evaluations—diameter, verticality, and sediment—in a single pass. This not only saved time but also reduced human error and simplified data interpretation.

4. Wireless, Portable, and User-Friendly

The device’s wireless CNC winch and WiFi-based control system made it highly portable and easy to deploy. Without the need for bulky external power supplies or cabling, the testing team could operate with flexibility across the entire construction site. The embedded Linux-based software system ensured stability and data reliability during long hours of operation.

5. Real-Time, On-Site Reporting

Time is critical on active construction sites. Thanks to its real-time printout functionality, the UDM device provided immediate visual reports including:

These outputs were instrumental for site engineers who needed to make real-time decisions based on borehole quality.

Project Impact: Quality Assurance at the Core

By detecting issues such as borehole deformation, sediment accumulation, or vertical misalignment early in the process, the UDM device enabled proactive corrections. This helped prevent downstream issues during pile installation and significantly reduced the risk of costly rework or structural failure.

Furthermore, by contributing reliable data, the UDM helped improve construction process planning and execution. The bridge foundation’s integrity—and ultimately the bridge’s safety—was directly linked to the success of this inspection technology.

A Testament to Engineering Excellence

The participation of the TS-K100CW UDM device in the Nan River bridge project underscores our commitment to innovation and quality in civil engineering solutions. The project served as a proving ground for our equipment’s robust performance in real-world conditions. The results speak volumes: smooth operation, high-quality data, and seamless integration into the project’s broader QA/QC workflow.

We captured the moment with high-resolution photos and videos of the UDM device in action. These materials will be showcased in our media gallery, illustrating not only the device’s capabilities but also our team’s expertise in on-site deployment and technical support.

Looking Ahead: Building Confidence in Foundation Testing

As infrastructure development accelerates across Southeast Asia and beyond, the demand for reliable geotechnical inspection technologies continues to grow. The TS-K100CW has already proven its worth in several major projects and is ready to support new ventures—from bridge and highway foundations to underground diaphragm walls and complex trench systems.

Whether you are a project manager, geotechnical consultant, or construction contractor, our UDM device offers peace of mind where it matters most: below the surface.