Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

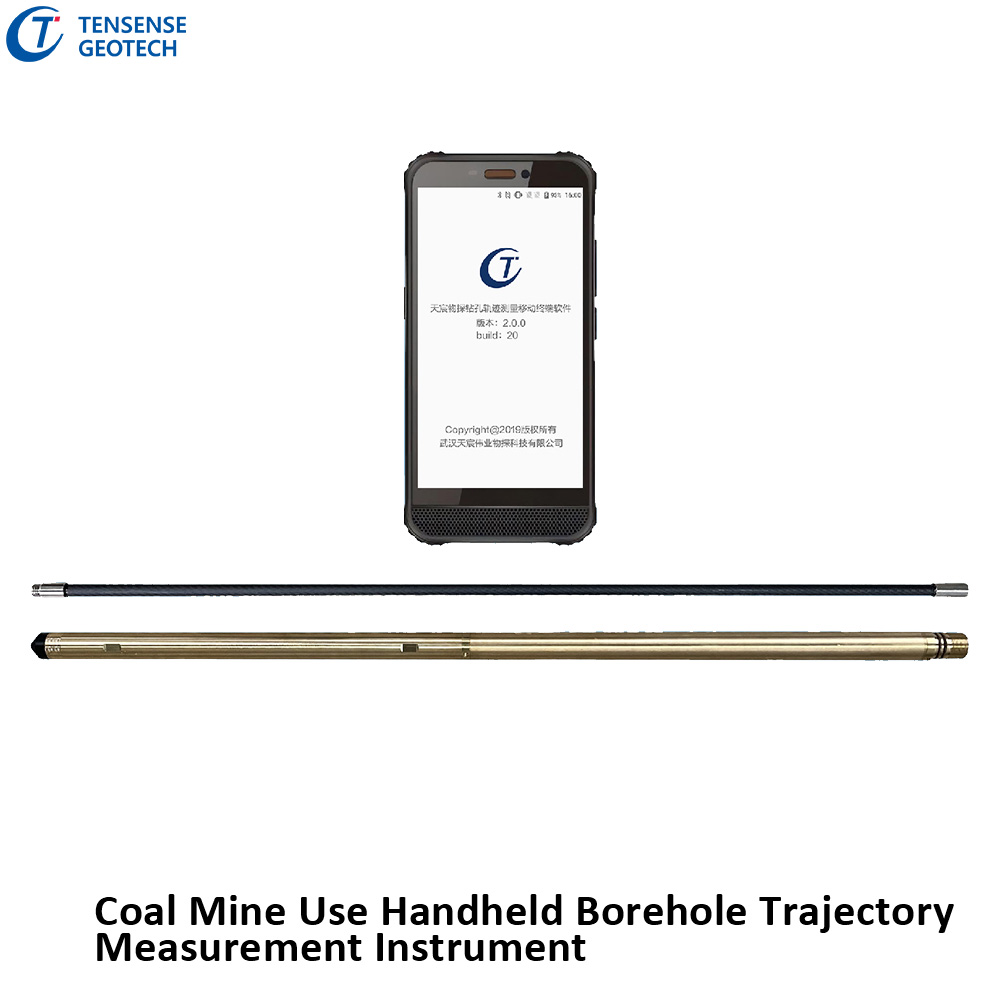

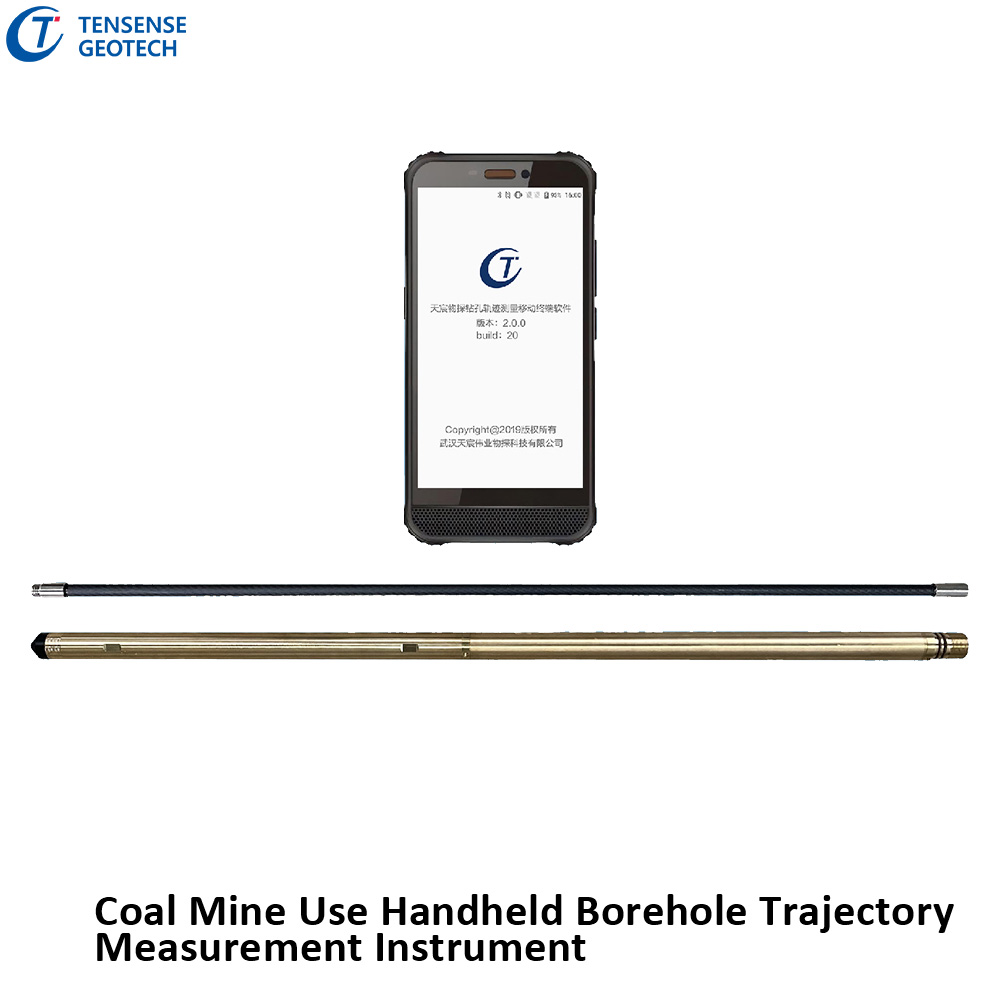

The Coal Mine Use Handheld Borehole Trajectory Instrument is a state-of-the-art device designed for precise and efficient measurement of borehole trajectories in underground mining operations. This innovative tool integrates advanced sensors, wireless communication technology, and portable hardware to provide real-time data on borehole spatial trajectories, depth, and azimuth angles. It is particularly suited for directional drilling, straight-hole drilling, and quality inspection in complex geological conditions. The primary goal of this device is to enhance the safety and efficiency of drilling operations in coal mines through accurate data collection and analysis.

Real-Time Trajectory Measurement: Equipped with a high-precision 3D electronic compass (tilt accuracy: 0.1°, azimuth accuracy: 0.5°), the device generates real-time 3D spatial trajectories of boreholes. Automatic Depth Detection: Supports two modes—automatic measurement using the probe’s built-in sensor or synchronized counting with the drilling rig, with an accuracy of ≤1 meter. Offline Re-Measurement Compatibility: No cables are required; the probe is manually pushed into the borehole using carbon fiber rods for measurement. Wireless Data Transmission: Bluetooth 5.0 technology enables seamless communication between the probe and the explosion-proof smartphone, eliminating the need for complex wiring in underground environments.

Lightweight and Efficient: The total weight is only 1.1kg (probe: 760g, smartphone: 248g, push rod: 105g), making it easy for a single operator to carry and use. Intrinsically Safe Design: Certified with Exib I Mb explosion-proof rating, suitable for gas-prone environments. Intelligent Analysis Software: Generates Word reports and exports Excel/CAD drawings with a single click, supporting unified management of borehole group data. Cloud Collaboration: Measurement data is uploaded to the cloud in real-time, facilitating remote team collaboration and historical record tracking.

| Component | Specifications |

|---|---|

| Probe (YZG12.8-T) | – Pressure resistance: ≥12MPa, continuous operation: >37 hours – Dimensions: Φ20mm×728mm, weight: 760g – Adjustable measurement interval: 1-60 seconds |

| Explosion-Proof Smartphone (KT653-S2) | – IP65 protection, octa-core processor, 6GB RAM – Dual rear cameras (13MP night vision), supports BeiDou positioning |

| Carbon Fiber Push Rod | – Material: Carbon fiber (tensile strength: ≥3.5GPa) – Length: 1m per rod, weight: 105g per rod |