Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Pile foundations play a critical role in construction, providing stability and load-bearing capacity for structures. Ensuring the quality of pile foundations is essential for structural safety, making pile integrity testing a crucial component of construction quality control. There are five primary methods for testing the integrity of concrete piles: the low-strain impact reflection method, crosshole sonic logging, core drilling, high-strain dynamic testing, and ultrasonic rebound method.

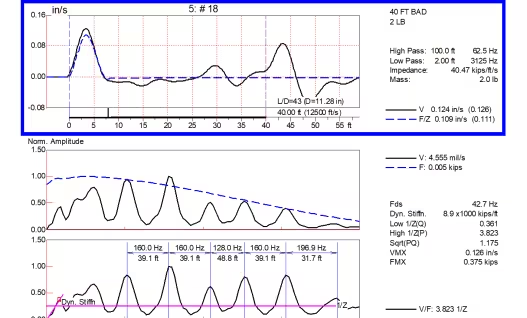

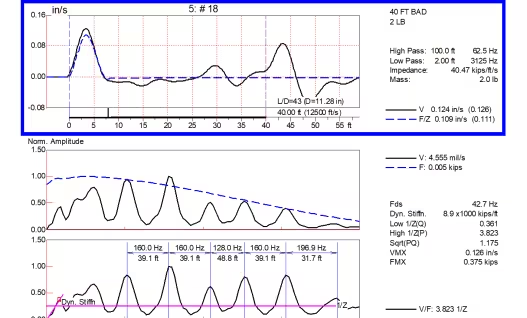

The low-strain impact reflection method is based on analyzing stress wave propagation within the pile. A small hammer strikes the pile head, generating a stress wave, and reflections from pile anomalies are captured and analyzed to assess pile length and integrity. The testing equipment typically includes a low-strain impact tester, sensors, and a data acquisition unit, and this method is straightforward, fast, and suitable for large-scale testing.

However, the low-strain method has limited depth detection capabilities and may struggle to accurately detect deep pile defects, especially in complex geological conditions. As a preliminary, non-destructive testing approach, it is mainly suited to assessing prefabricated and cast-in-situ piles but lacks the precision required for rigorous engineering projects.

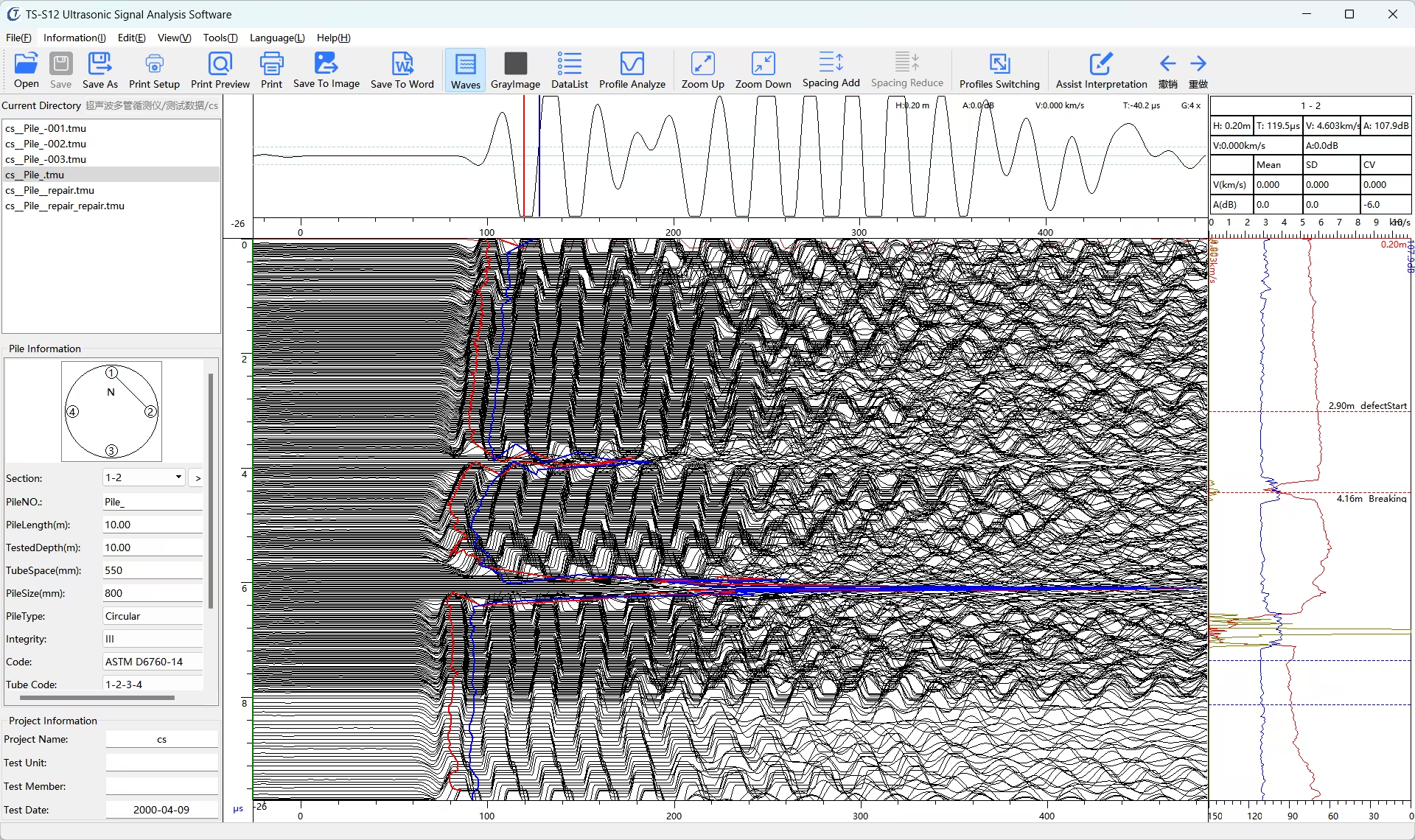

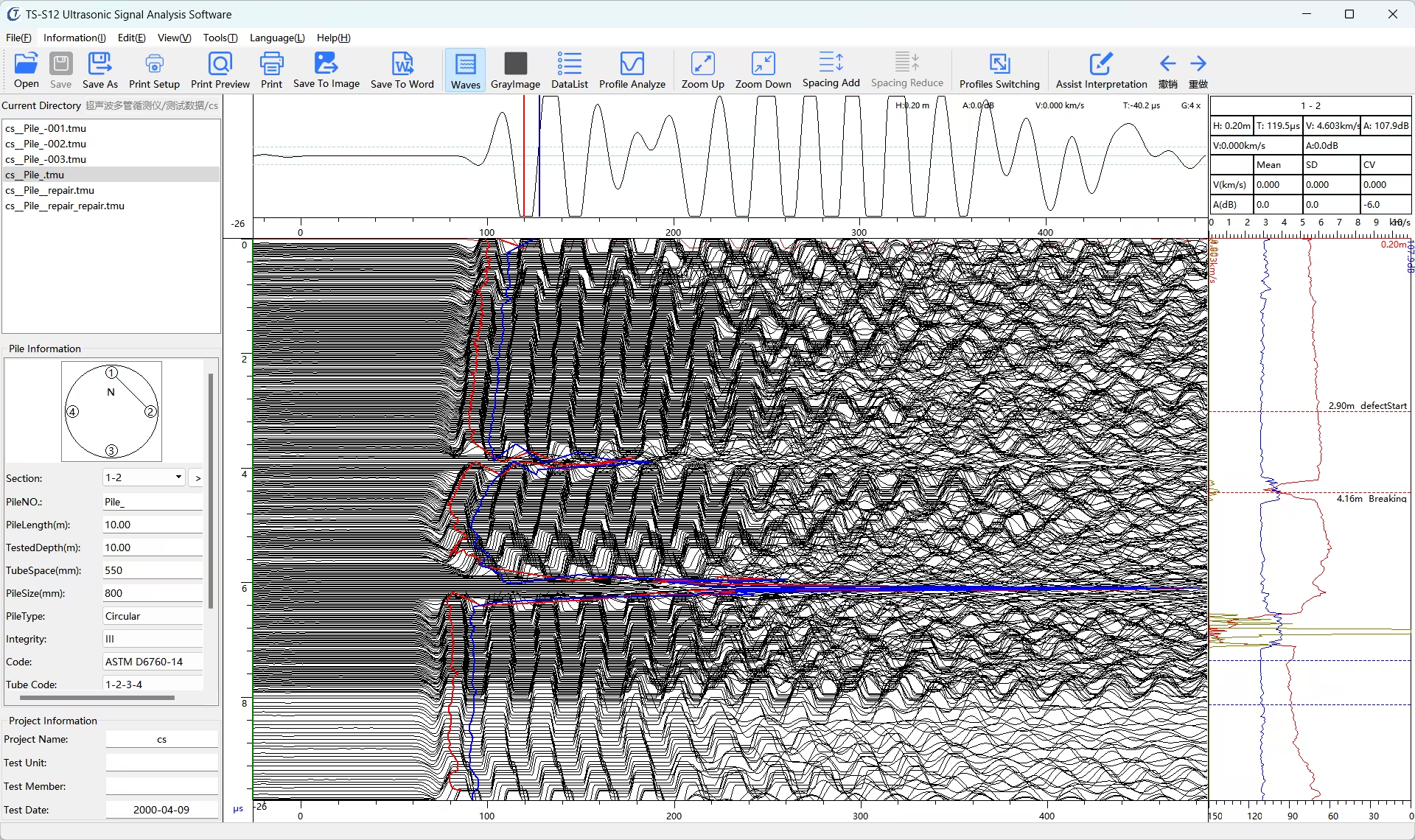

Crosshole sonic logging (CSL) is widely regarded as one of the most effective methods for concrete pile integrity testing, particularly in high-stakes projects. CSL works by embedding access tubes in the pile, through which ultrasonic transducers are lowered to measure sound wave travel times and attenuation. Variations in wave travel times help identify anomalies such as voids, inclusions, and cracks within the pile.

Advantages of Crosshole Sonic Logging

Tensense crosshole sonic logging device is based on advanced acoustic principles, featuring max 4pcs high-precision probes and an intelligent analysis program that delivers fast, efficient testing across a range of complex pile configurations. Designed to comply with both national and international standards, it is suitable for assessing concrete piles in diverse construction scenarios.

Applications of Crosshole Sonic Logging

CSL is commonly used in subways, elevated highways, large foundation projects, and ports, where structural integrity and safety are paramount. It is especially suitable for large-diameter and deep piles, as well as re-evaluation of foundation piles, providing a significant boost in construction safety.

The core drilling method is one of the most direct and reliable techniques for pile integrity testing, as it allows physical inspection of concrete cores extracted from the pile. Using a coring machine and associated lab equipment, core samples are analyzed for compressive strength and integrity, providing a dependable measure of pile quality.

While core drilling is highly reliable, it is a destructive testing method that damages the pile structure to some degree, and it can be costly. As a result, core drilling is typically reserved for quality verification of high-priority piles, rather than large-scale testing.

High-strain dynamic testing (PDA) involves the application of a large force at the pile head, with resulting stress and velocity data used to assess both pile capacity and integrity. The high-strain dynamic testing setup includes a PDA analyzer, sensors, and a hammer for pile driving. This method can test a wide range of piles and assess both pile strength and integrity in a single operation.

While suitable for large-scale testing, high-strain testing can be costly and requires skilled technicians to operate. It is best suited for large, complex projects that require comprehensive pile assessment.

The ultrasonic rebound method combines ultrasonic testing and surface rebound measurements to evaluate concrete quality by analyzing sound wave propagation and rebound values. The required equipment typically includes an ultrasonic tester and a rebound hammer, making this method portable and user-friendly.

However, the ultrasonic rebound method is limited to surface testing and cannot effectively assess internal pile conditions. Therefore, it is often used as an auxiliary test to complement other methods.

Summary of above 5 methods

Testing Method | Advantages | Disadvantages |

Low-Strain Impact Reflection | 1. Simple and quick to perform | 1. Limited depth penetration |

Crosshole Sonic Logging (CSL) | 1. High precision, even in deep piles | 1. Requires preinstalled access tubes |

Core Drilling | 1. Direct and highly reliable | 1. Destructive, with potential pile damage |

High-Strain Dynamic Testing | 1. Simultaneous assessment of load capacity and integrity | 1. Higher cost and technical expertise required |

Ultrasonic Rebound Method | 1. Portable and easy to use | 1. Limited to surface testing |

Conclusion

Each pile integrity testing method has its unique strengths and applications. The low-strain impact reflection method, core drilling, high-strain testing, and ultrasonic rebound method all serve distinct needs across different scales and types of pile testing. Among them, crosshole sonic logging stands out for its high precision, multi-angle coverage, and deep inspection capabilities, making it one of the most widely used and reliable pile integrity testing methods today. Tensene crosshole sonic logging device incorporates advanced detection and data analysis technology, making it ideal for projects with complex geological conditions or strict quality standards.

If you are seeking a reliable and high-precision solution for pile integrity testing, crosshole sonic logging is the premier choice. We highly recommend the crosshole sonic logging device and look forward to supporting construction projects with enhanced safety and quality assurance.