Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

The TS-CG30(C) Smart Pile Cap Concrete Overpouring Monitoring Instrument is a cutting-edge device designed to address the critical issue of overpouring in pile foundation construction. This innovative equipment is intended to monitor the concrete pouring process at the pile cap level, ensuring that the concrete is placed accurately and efficiently, thereby preventing overpouring and the associated waste of materials as well as increases in project costs.

The system consists of a sensor probe and a main control unit, which work together to provide real-time data on the concrete’s level. When the concrete reaches the desigh height, the device triggers an audible and visual alarm, alerting the construction crew to stop pouring. This immediate feedback mechanism is essential in maintaining the structural integrity of the foundation while optimizing material usage.

Advanced Real-Time Monitoring Features

Our advanced sensor tracks the concrete level while it’s being poured. This instant feedback helps us know exactly when the concrete hits the right height, allowing us to stop pouring at the perfect time. This accuracy saves materials and maintains the strength and quality of the pile foundation.

Durable and User-Friendly Design

Engineered to withstand the harsh conditions of construction sites, the Pile Concrete Overpour Monitor features a robust and lightweight construction that is both durable and portable. The device is designed with user convenience in mind, offering an intuitive control panel that is easy to operate, even for workers with limited technical expertise

Affordable and Eco-Friendly Solution

By removing guesswork and the risk of overpouring, the Pile Concrete Overpour Monitor helps save concrete in each pile, which leads to lower costs for construction projects. Moreover, by reducing concrete waste, this device supports a more sustainable construction process, matching the industry’s move towards greener practices. This not only aids the project’s budget but also promotes environmental responsibility.

Main Applications:

Industrial Construction: In the realm of industrial development, where the construction of robust infrastructure is paramount, the Pile Concrete Overpour Monitor plays a pivotal role. It is utilized in the construction of factories, warehouses, and other large-scale industrial complexes where the foundation’s integrity is crucial for the structure’s longevity and safety. By monitoring the concrete pouring process, the device ensures that the piles are filled accurately, preventing overpouring that could lead to unnecessary costs and potential structural weaknesses.

Municipal and Public Works Projects: The device is extensively applied in municipal construction projects such as bridges, roads, and other public utilities. These projects often involve extensive pile driving and concrete pouring, where the stakes are high in terms of public safety and project durability. The Pile Concrete Overpour Monitor’s ability to provide real-time monitoring and immediate alerts helps to maintain the quality of the work, ensuring that public infrastructure is built to last and withstand the test of time.

Residential Construction: With the growing demand for housing and the importance of cost-effective construction, the Pile Concrete Overpour Monitor is invaluable in residential building projects. From single-family homes to multi-story apartment complexes, accurate foundation work is essential. The device helps to control the cost of construction by minimizing material waste and ensuring that the concrete is applied optimally, contributing to the construction of safe and stable residential structures.

Commercial Development: In commercial construction, where projects often involve complex designs and significant investment, the Pile Concrete Overpour Monitor is employed to ensure that the foundational work is executed with precision. Its application in the construction of shopping centers, office buildings, and other commercial spaces helps to uphold high-quality standards while keeping project costs in check.

Infrastructure Expansion and Rehabilitation: The Pile Concrete Overpour Monitor is also utilized in the expansion and rehabilitation of existing infrastructure. Whether it’s upgrading transportation networks or reinforcing existing structures, the device provides the necessary monitoring to ensure that new pile installations are carried out without overpouring, thereby preserving the integrity of the overall construction work.

Features:

Enhanced Precision and Efficiency: The Pile Concrete Overpour Monitor employs advanced sensing technology to provide precise real-time data on the concrete pour levels. This level of precision ensures that the concrete is placed exactly where it is needed, when it is needed, thereby optimizing the efficiency of the construction process. The device’s immediate alert system to signal the cessation of pouring upon reaching the set level virtually eliminates the risk of overpouring, which can compromise the structural integrity and lead to costly rework.

Cost Reduction and Material Conservation: By preventing overpouring, the Pile Concrete Overpour Monitor significantly reduces the amount of concrete used in construction projects. This not only cuts down on material costs but also aligns with sustainable construction practices by minimizing waste. The savings accumulated from reduced material usage can be redirected to other areas of the project, enhancing the overall budgetary efficiency.

Ease of Use and Adaptability: The device is designed with user-friendliness in mind, featuring an intuitive control interface that can be easily managed by construction crews with varying levels of technical expertise. Its adaptability allows it to be seamlessly integrated into a variety of construction environments and project scales, from small residential developments to large industrial complexes.

Durability and Reliability: Constructed with robust materials, the Pile Concrete Overpour Monitor is built to last and perform under challenging site conditions. Its durability ensures consistent and reliable operation, even in extreme temperatures and demanding work environments. The device’s resilience to wear and tear guarantees a long service life, making it a worthwhile investment for construction firms.

Support for Sustainable Construction Practices: By facilitating the reduction of concrete waste, the Pile Concrete Overpour Monitor contributes to the broader goals of sustainability within the construction industry. Its role in promoting efficient use of resources and minimizing environmental impact aligns with the global movement towards greener construction methods and supports the industry’s transition towards more eco-friendly practices.

Increased Safety and Structural Integrity: The device’s ability to prevent overpouring ensures that pile foundations are constructed according to design specifications, which is critical for the long-term stability and safety of the structures built upon them. By maintaining the correct concrete levels, the Pile Concrete Overpour Monitor helps to avoid potential structural issues that could arise from improper foundation work.

Technical Introduction:

Power Requirements: The monitor operates on a DC voltage of 12V, ensuring compatibility with standard power supplies commonly used in construction settings. This voltage is optimal for the device’s electronic components, providing stable and consistent power for its operations.

Current Draw: The device is designed to consume a current of less than 1 ampere (A). This low power consumption is beneficial for energy efficiency, reducing the overall energy requirements for the construction site and contributing to cost savings.

Operating Temperature Range: The Pile Concrete Overpour Monitor is built to withstand and function effectively in a wide temperature range, from -10°C to +60°C. This robust temperature tolerance ensures that the device can be used in various climates and weather conditions without compromising its performance.

Working Duration: With an operating duration of over 4 hours, the device is capable of sustained monitoring sessions without the need for constant recharging or external power. The built-in lithium battery provides this autonomy, and the option for external power supply ensures that the device can continue to operate even when the battery is depleted.

Detection Depth: The standard configuration of the device allows for a detection depth of 30 meters, which is suitable for most pile foundation projects. However, customization options are available to accommodate deeper or shallower pile requirements, ensuring that the device can be tailored to specific project needs.

Control Interface: The device features a user-friendly panel with buttons for easy operation and navigation. This straightforward interface allows construction crews to operate the monitor with minimal training, reducing the potential for user error and enhancing the efficiency of the monitoring process.

Alarm Indication: Upon detecting that the concrete has reached the preset level, the Pile Concrete Overpour Monitor provides an immediate indication through both audible and visual alarms. This dual alarm system ensures that the signal is unmistakable, even in noisy construction environments.

Physical Dimensions and Weight: The probe of the device measures 48mm in diameter by 482mm in length, while the main control unit is 350mm long, 214mm wide, and 440mm high. The probe weighs approximately 2.5 kilograms, and the main control unit weighs around 6 kilograms. These dimensions and weights are designed to ensure that the device is portable and easy to handle during construction activities.

Accessories and Packaging: The device comes complete with a charger, several ties for securing the probe, a data transmission cable, vacuum-sealed silicone grease for maintaining the probe’s integrity, a durable aviation case for storage and transport, spare seals, a certificate of conformity, and an instruction manual.

Uploading…

Highly adaptable for a wide range of geotechnical applications, providing consistent and reliable results in diverse subsurface environments.

The probe is small in diameter and can reach the hard rock stratum at the bottom of the pile.The probe has a built-in inclination sensor to ensure that the probe is upright.

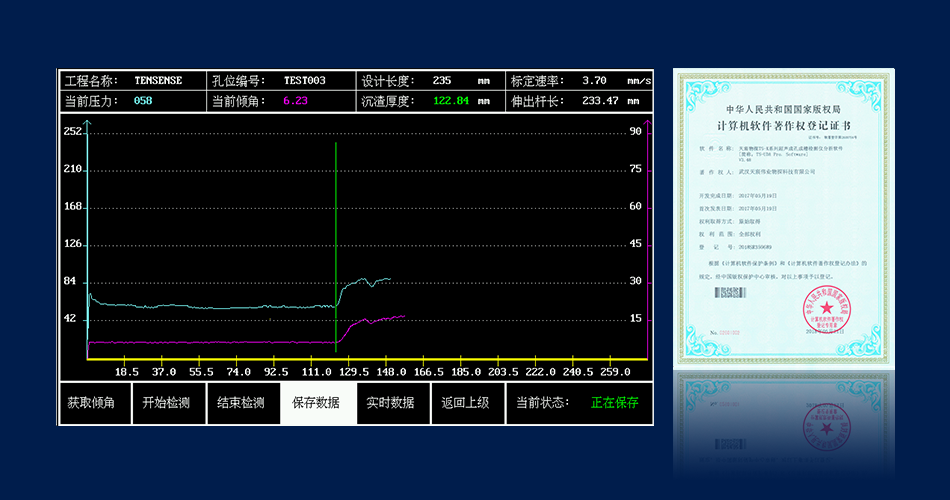

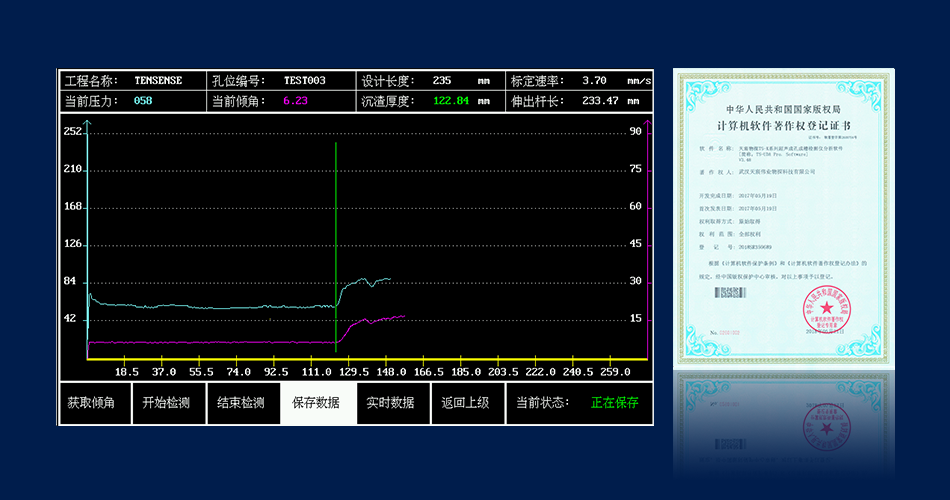

real-time graphical representation of depth pressure curves and inclination metrics, facilitating straightforward identification of sediment thickness.

Main Applications:

Features:

Technical Introduction:

Comprehensive Application Scope: The TS-K100CZ(A) is versatile, suitable for sediment thickness detection across various hole and trench configurations, unaffected by the subterranean medium’s characteristics.

Optimized Measurement Precision: With a minimal influence from external factors, the device boasts high accuracy in measurement. The slender probe design facilitates reaching the bedrock at the hole’s base, while the probe’s tray ensures stable contact with the sediment surface. The integrated angle sensor maintains the probe’s vertical alignment, resulting in sediment thickness measurements with an accuracy of up to 0.1mm.

Real-Time Data Visualization: The TS-K100CZ(A) provides an intuitive display of the pressure-tilt angle curve and the probe’s extension length, enabling immediate and precise determination of sediment depth.

Uploading…