Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

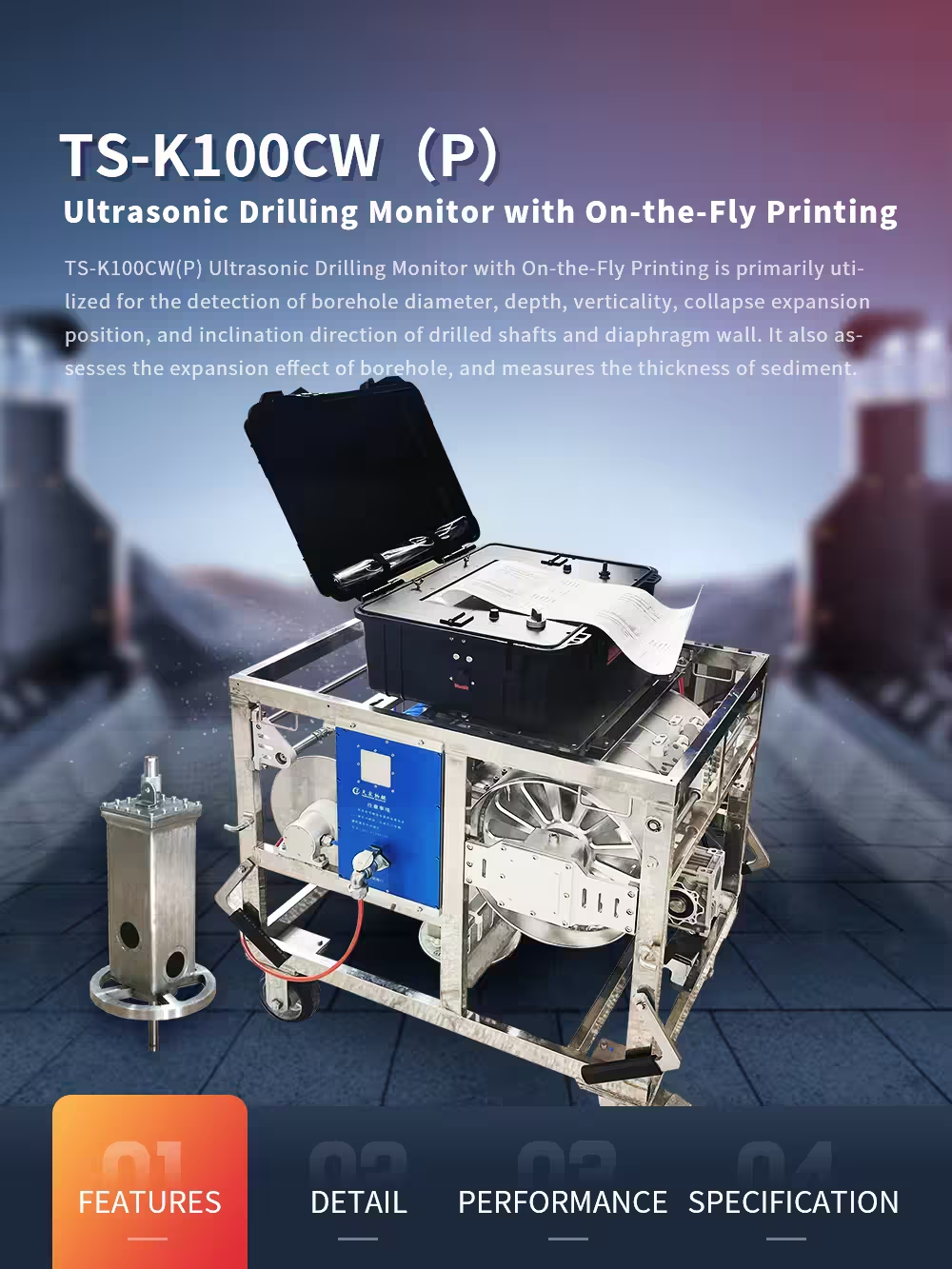

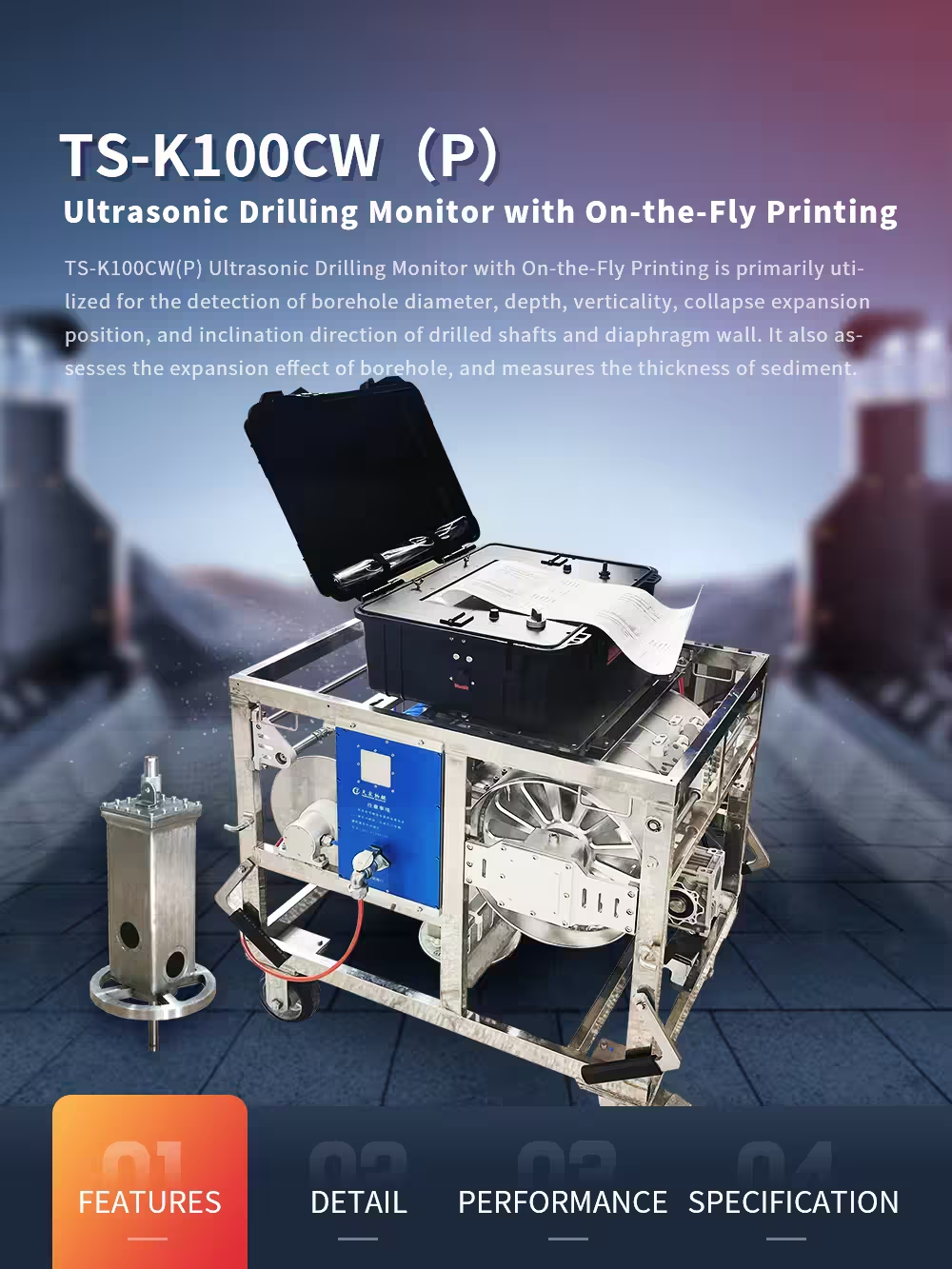

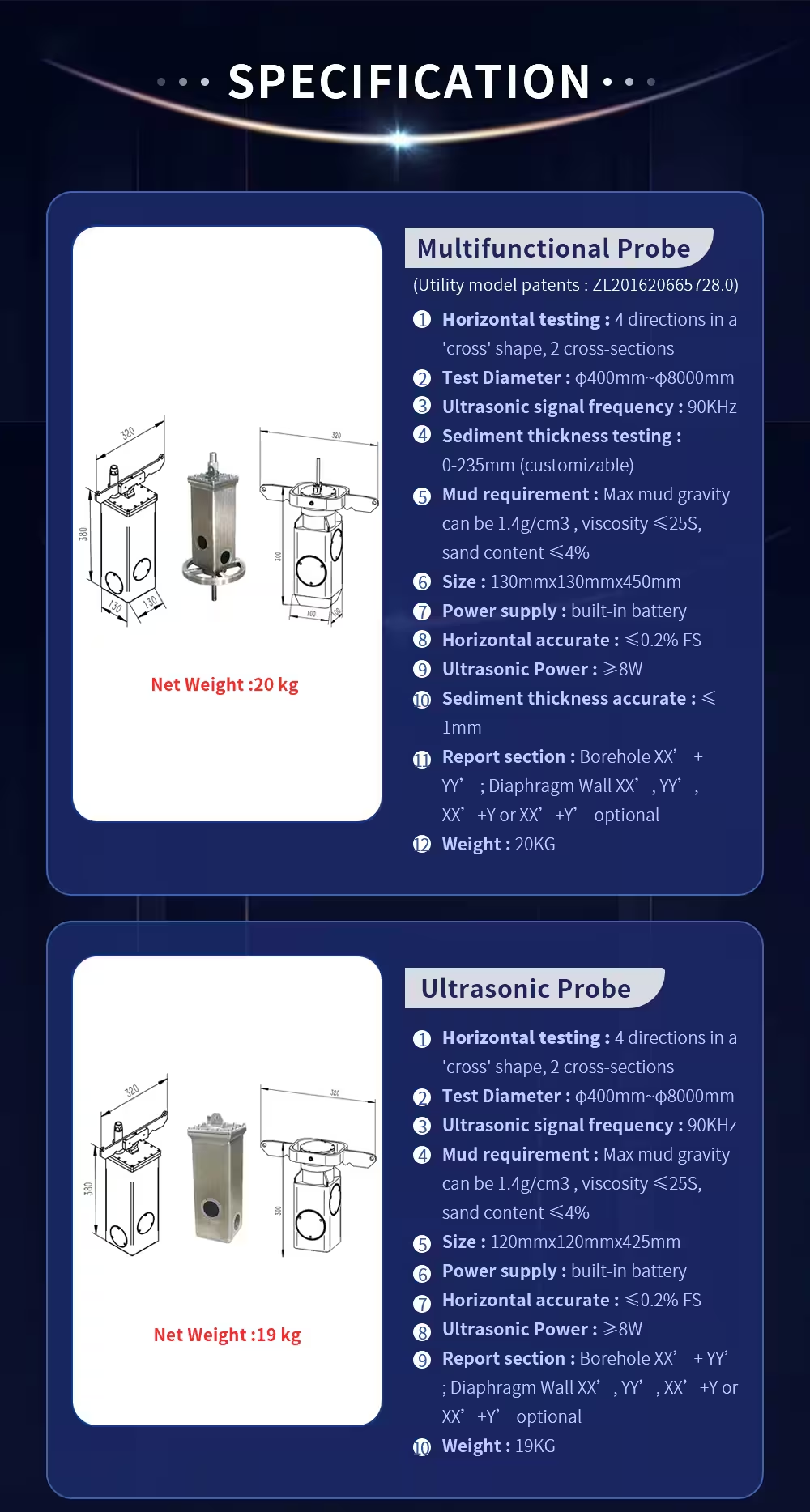

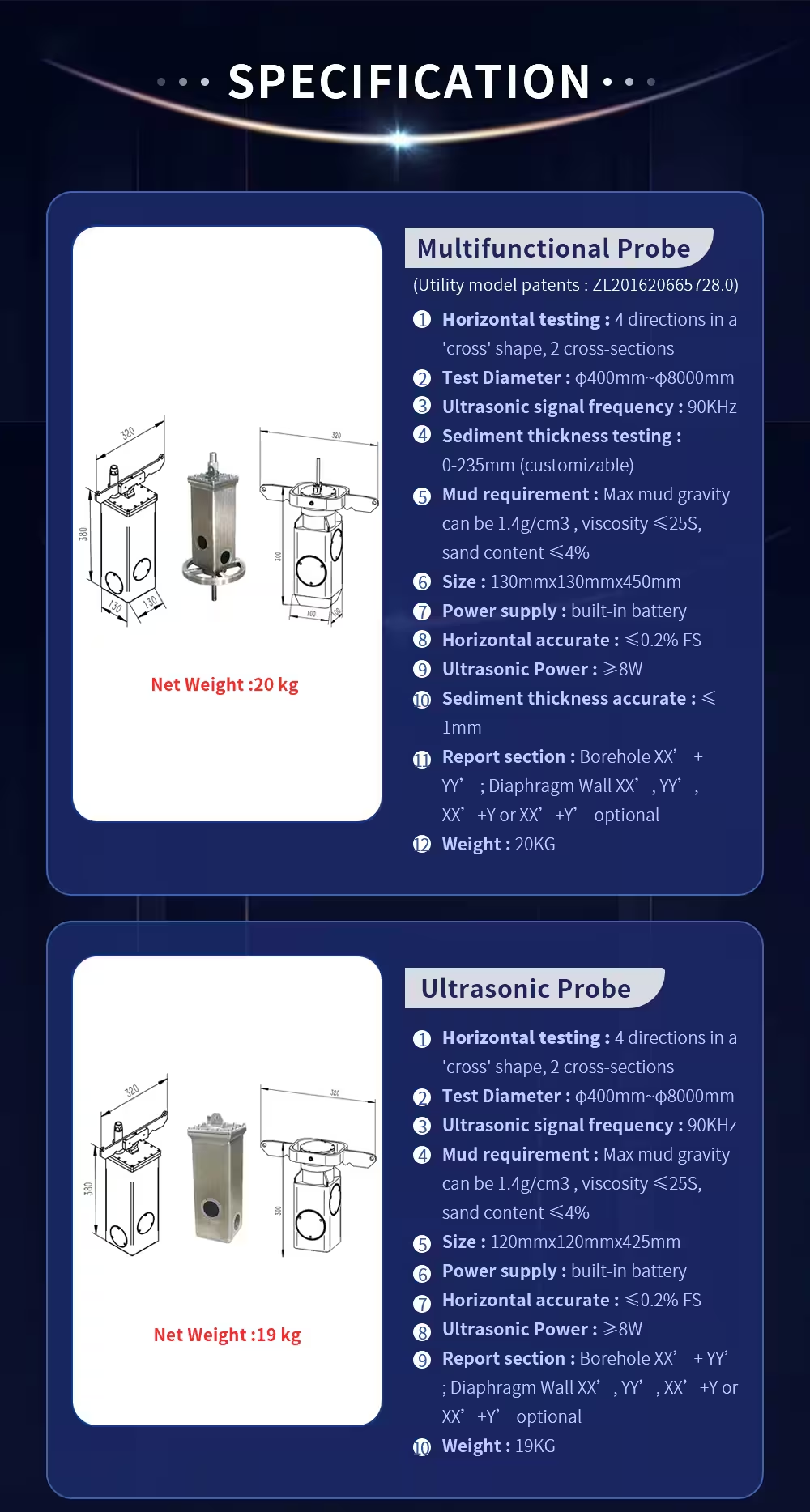

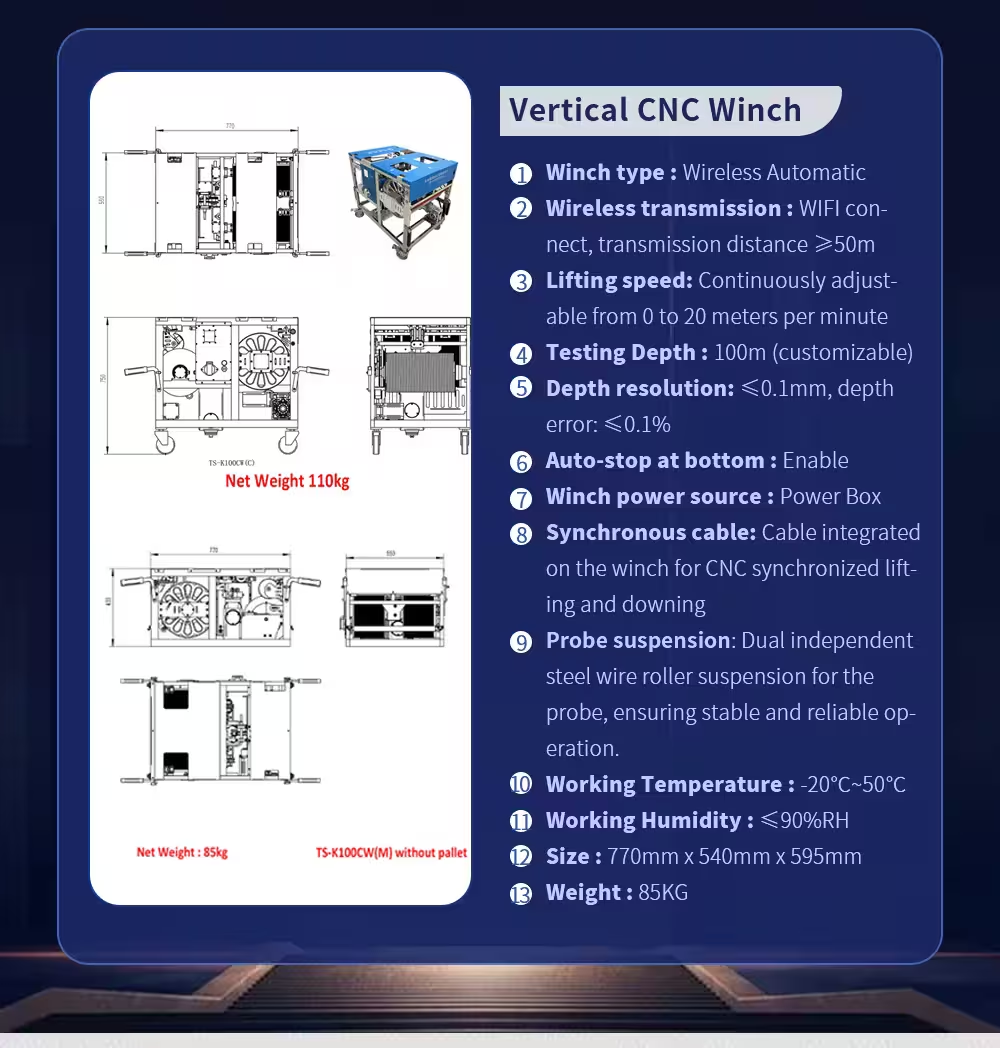

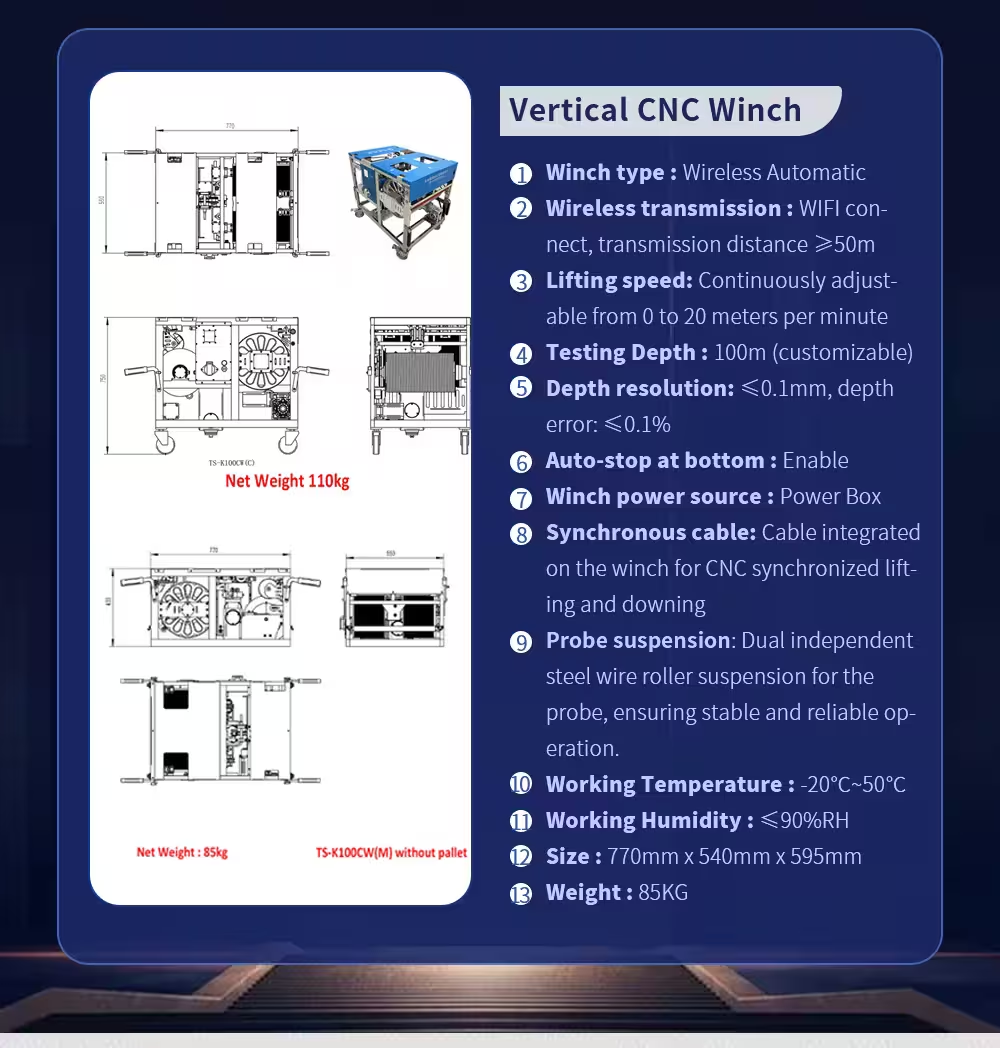

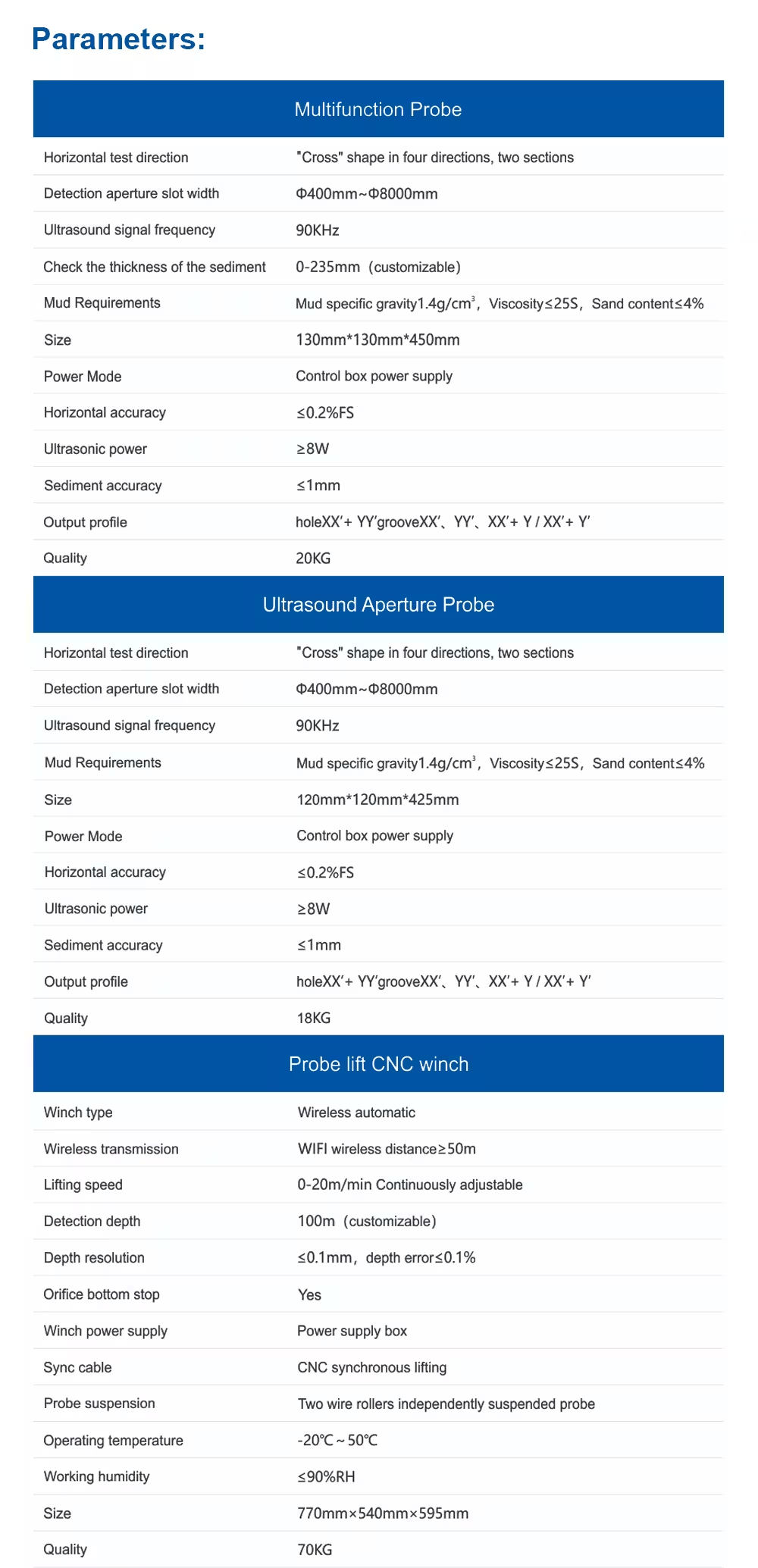

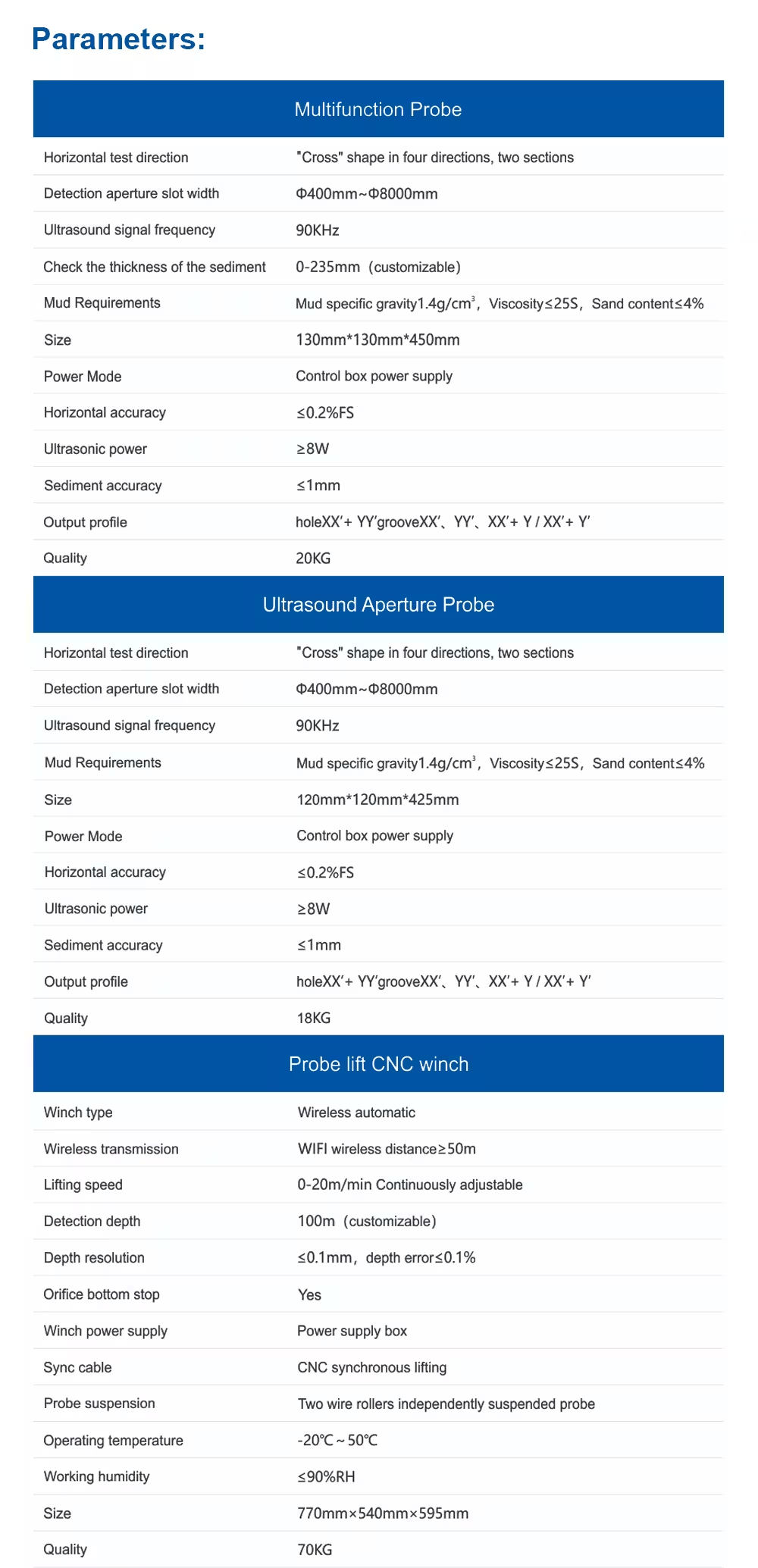

The TS-K100CW(P) Borehole Drilling Monitor is an advanced borehole drilling testing, inspection, and quality control system designed for industrial and geotechnical drilling applications. Ensuring drilling accuracy, borehole integrity, and structural compliance is critical for foundation stability and overall project success. This system provides real-time borehole drilling assessment, detecting deviations, sediment accumulation, and verticality issues to prevent costly errors and improve efficiency.

With ultrasonic and sensor-based monitoring, the TS-K100CW(P) enhances industrial borehole drilling inspection and quality evaluation in both dry and wet borehole conditions. It automates borehole drilling quality management, delivering accurate data logging, in-depth reporting, and cloud-based quality control tracking. Whether for industrial projects or wet drilling environments, this system ensures precise borehole drilling quality assessment and compliance with engineering standards

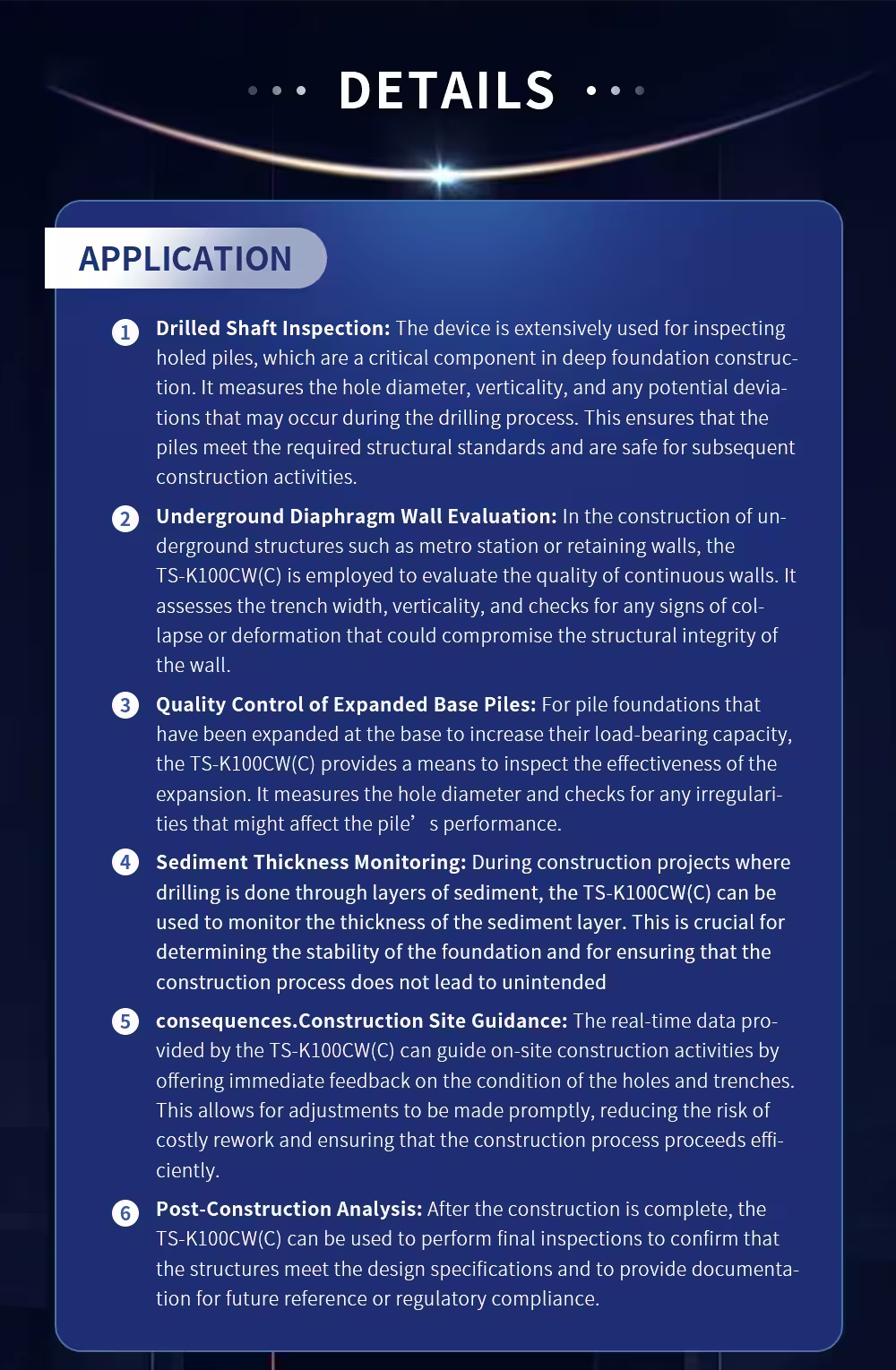

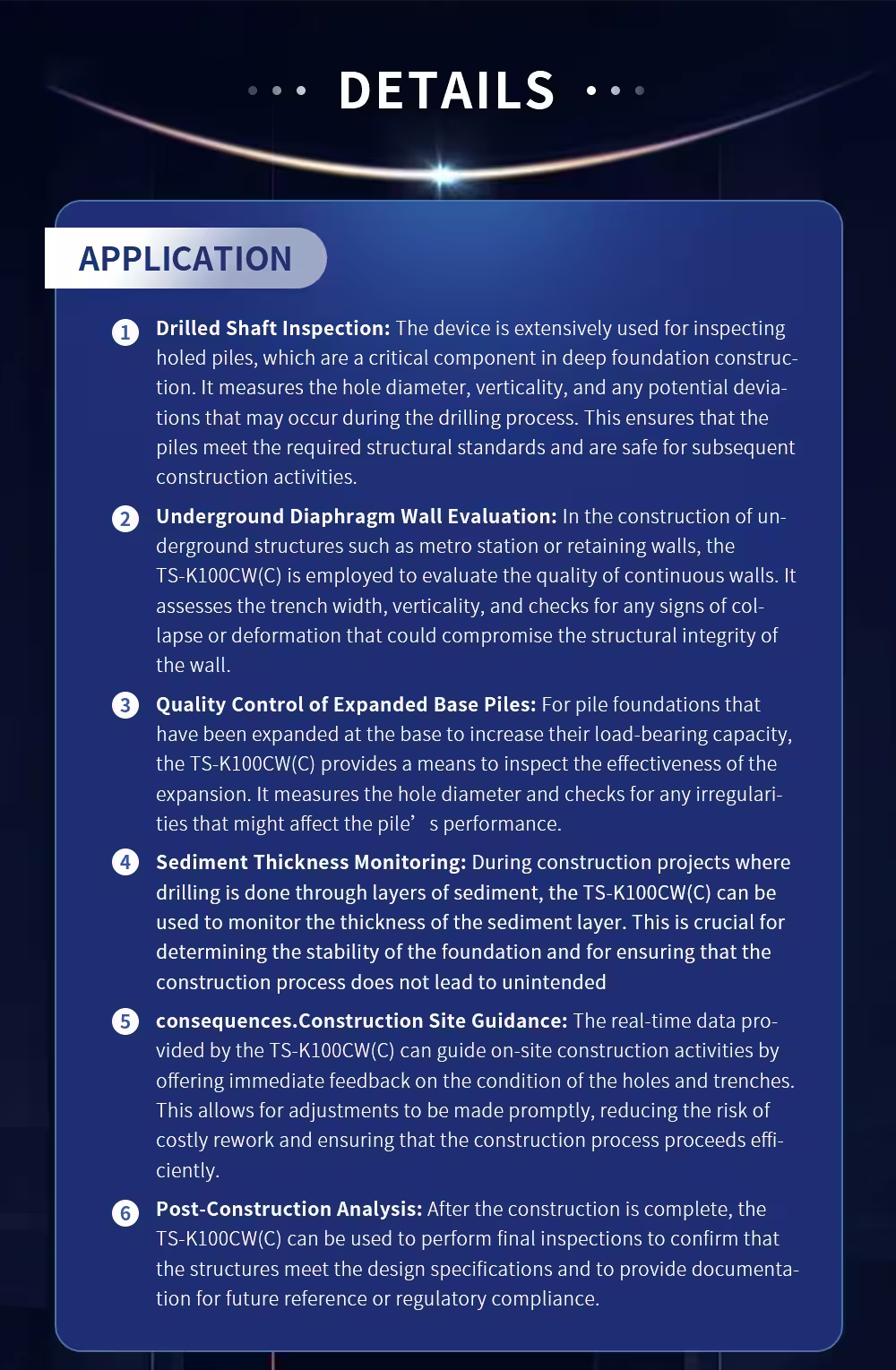

Applications :

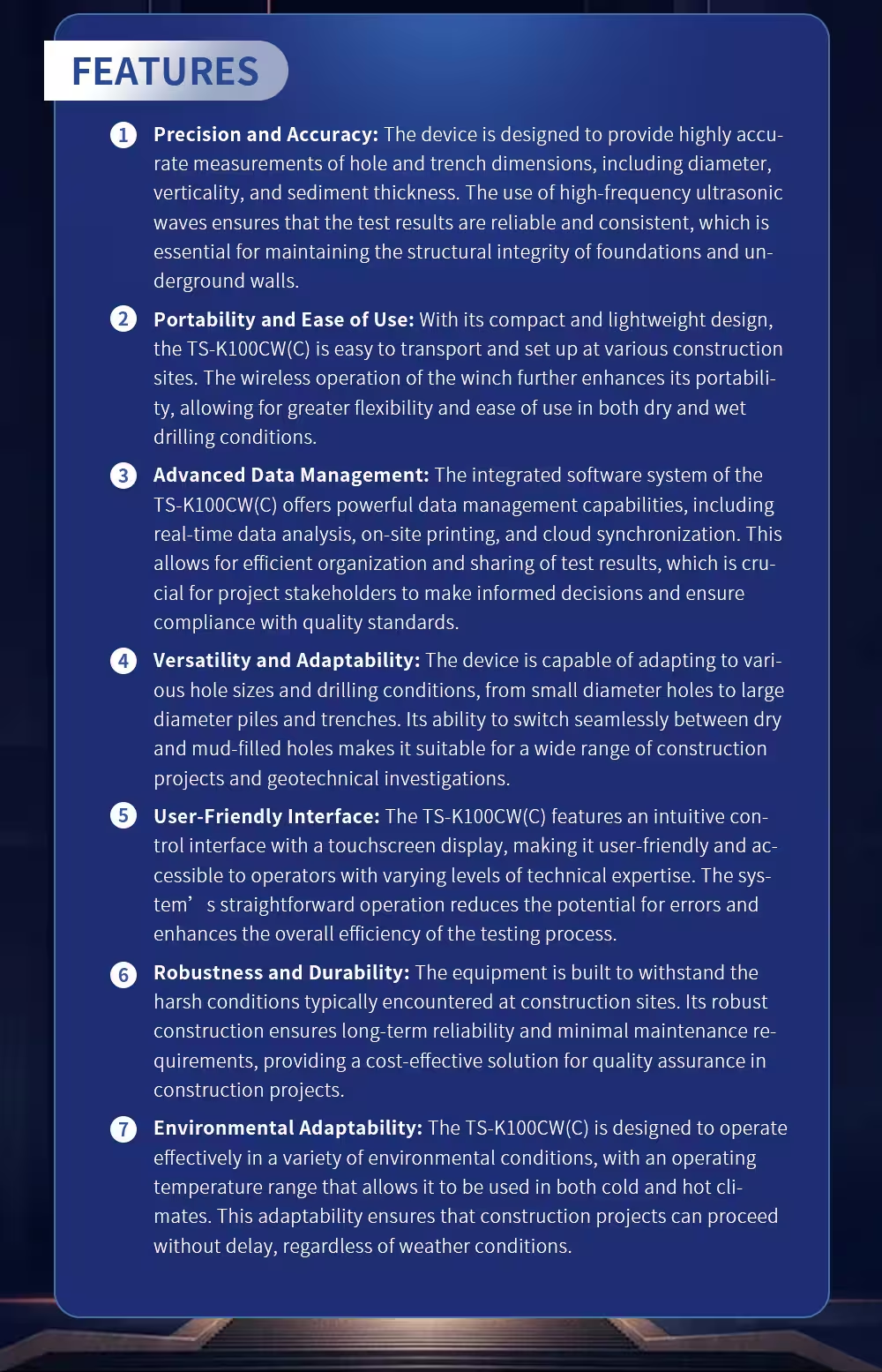

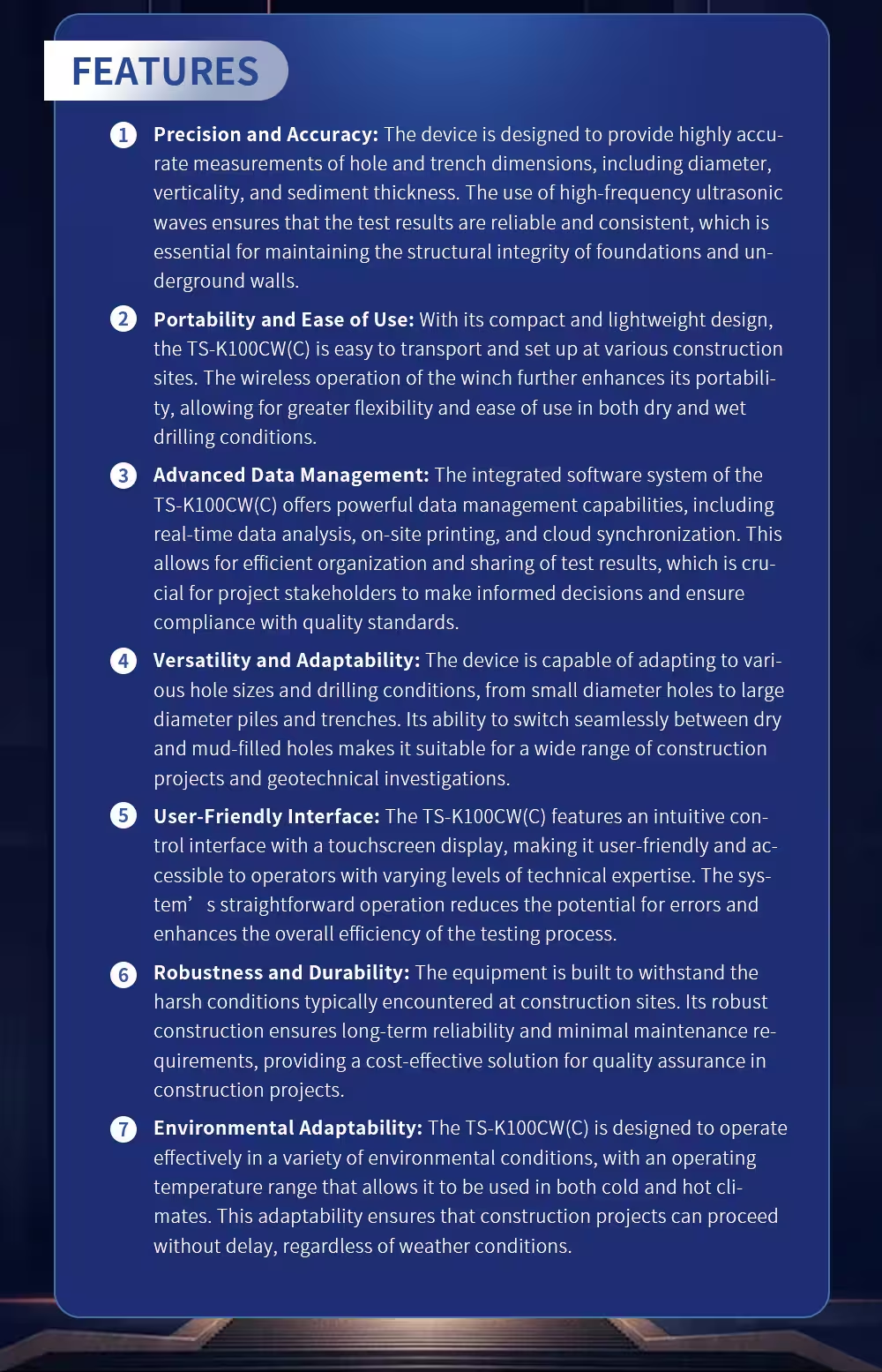

Features :