Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

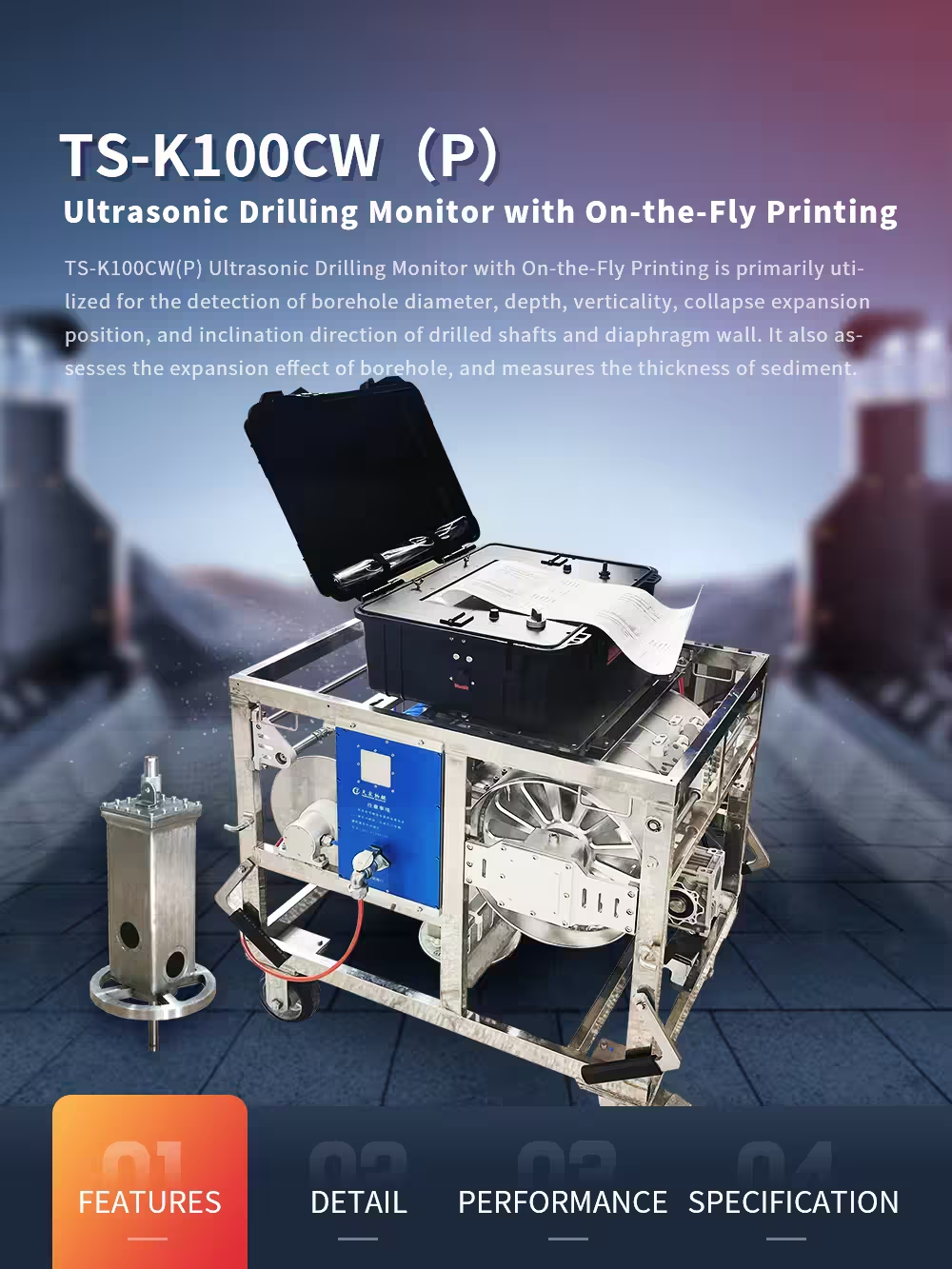

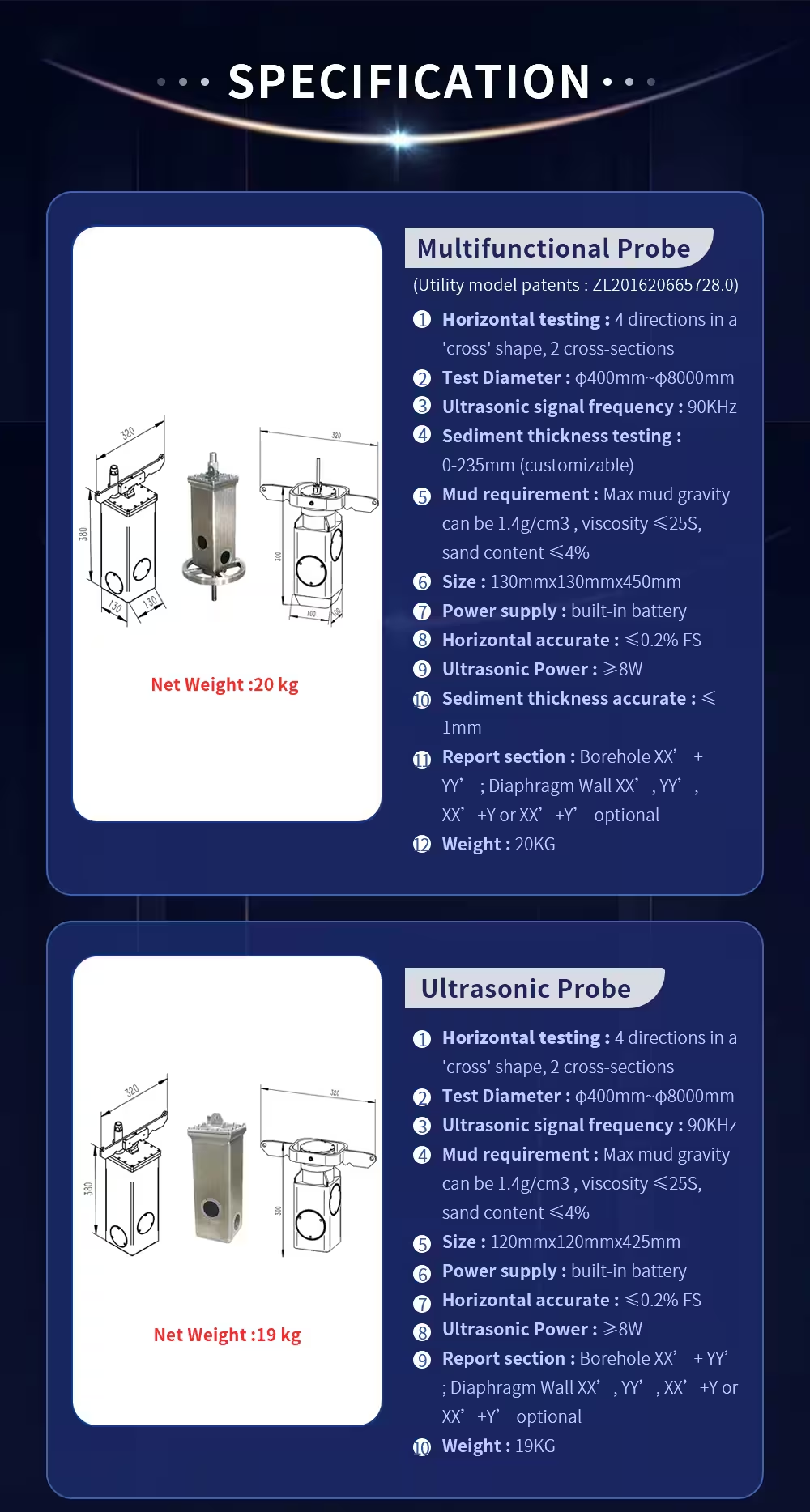

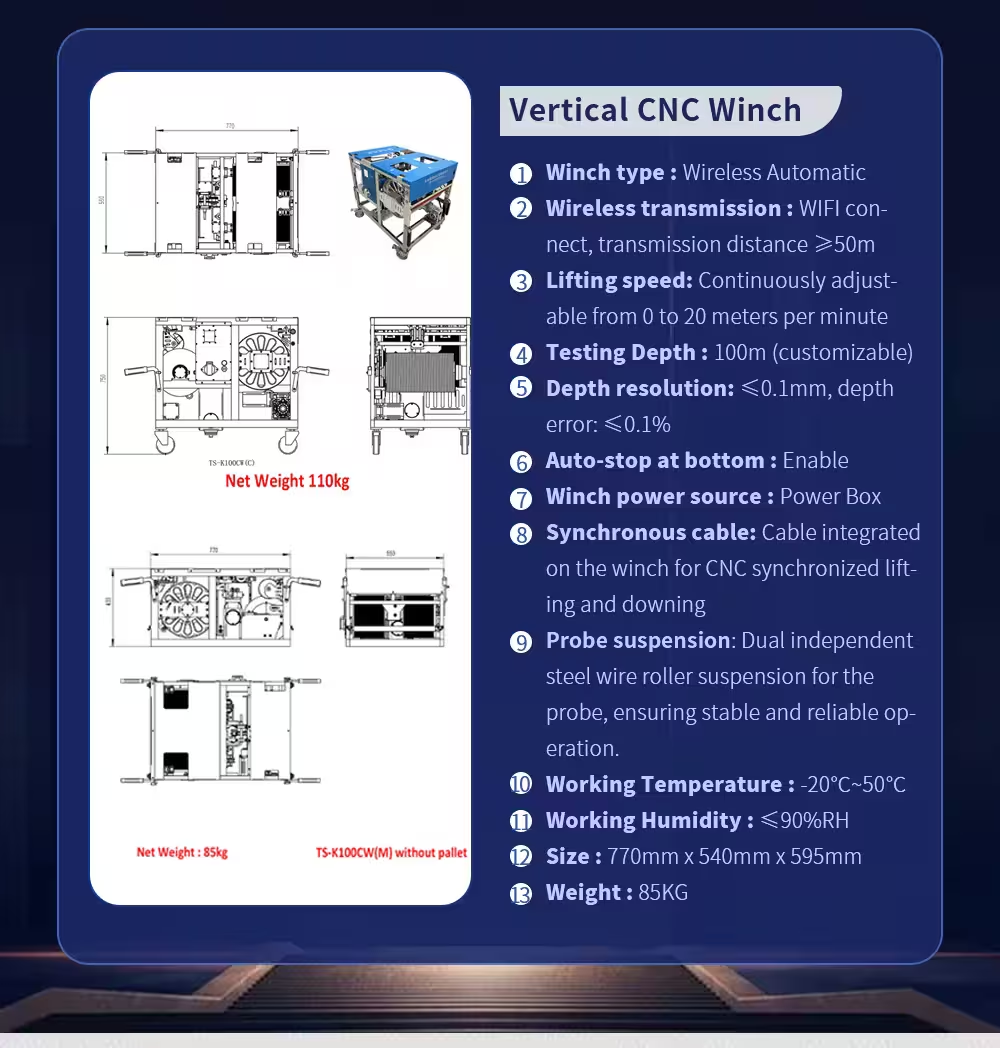

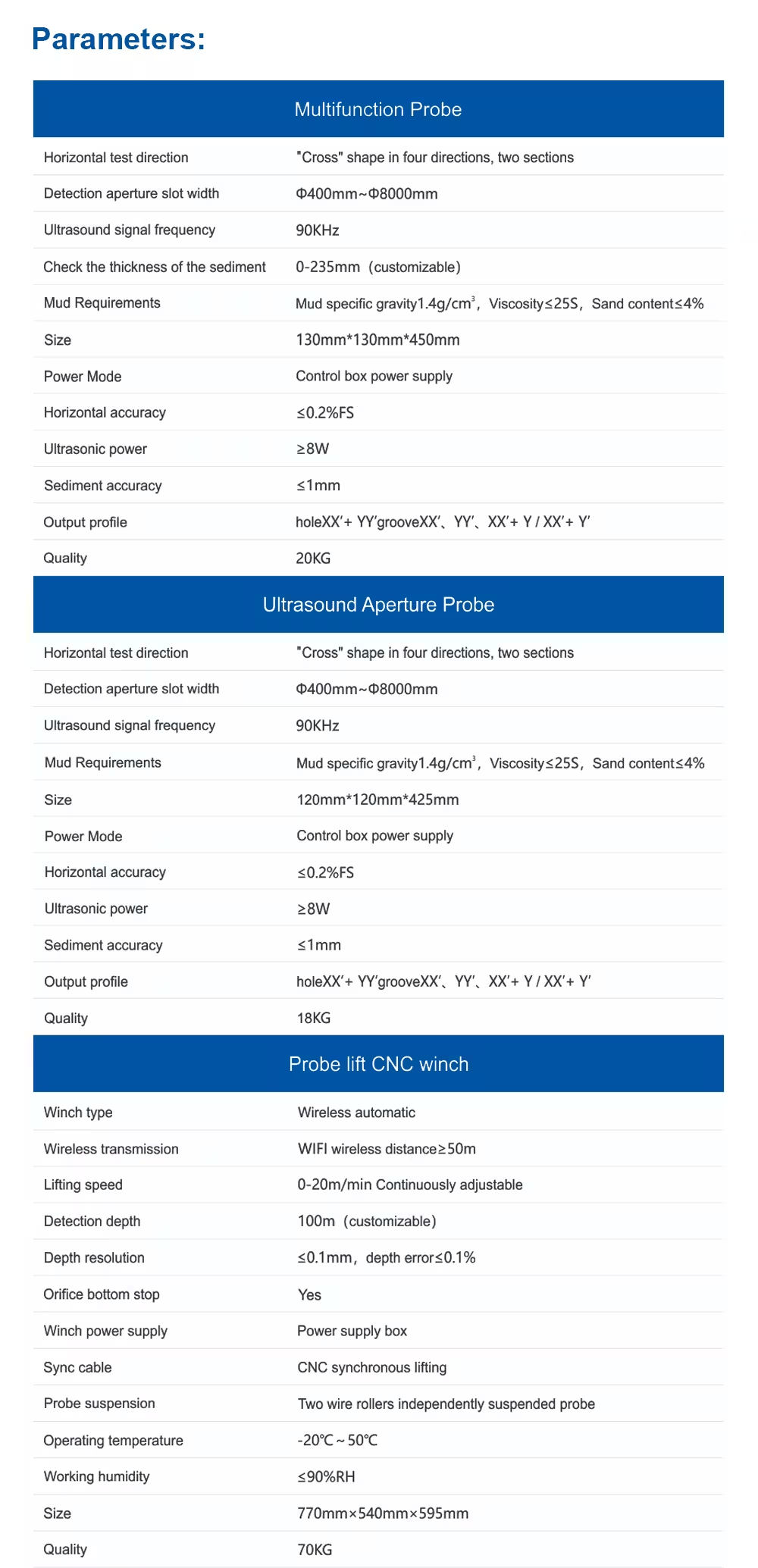

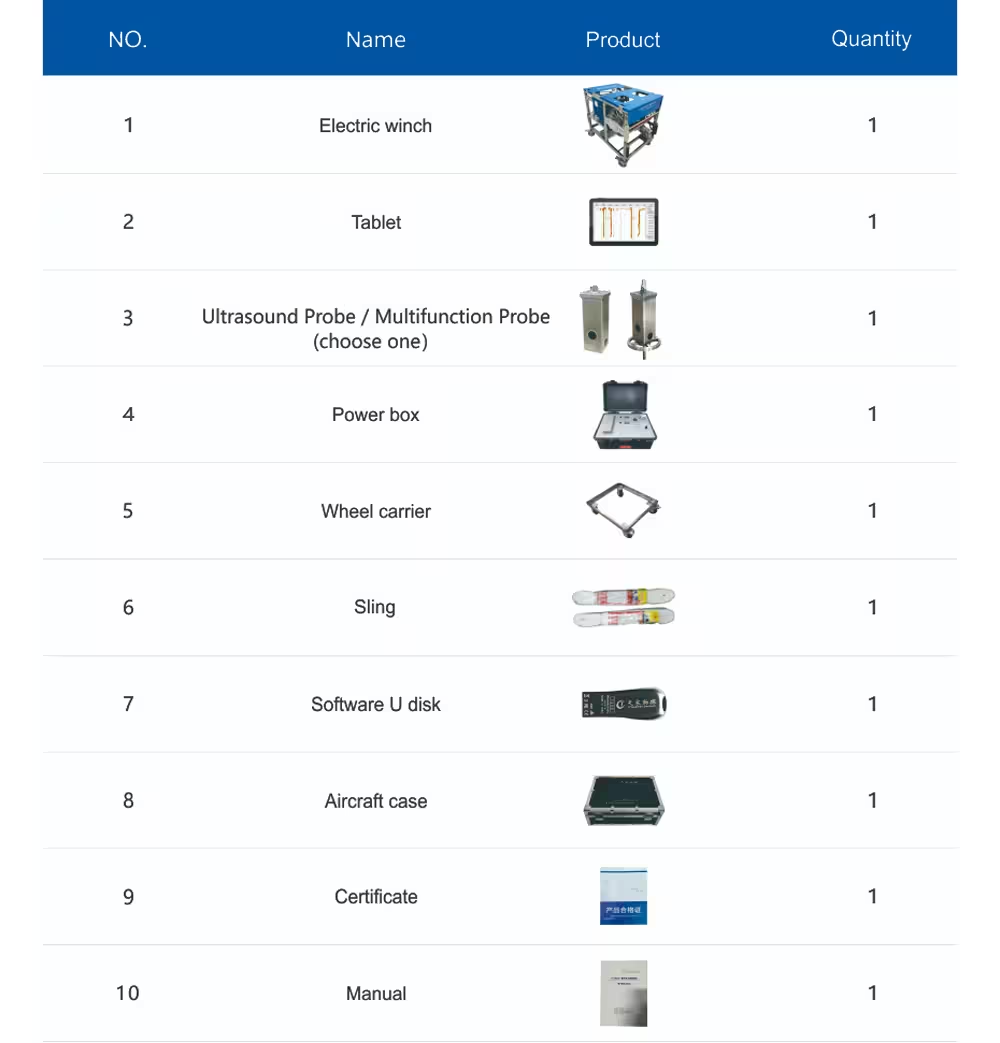

The TS-K100CW(P) Ultrasonic Borehole Size Monitor is an advanced system designed for borehole size testing, inspection, and quality control in drilling and construction projects. Ensuring the correct borehole diameter, depth, verticality, and structural integrity is critical for foundation stability and overall project success. This system provides real-time data and automated analysis, allowing engineers to detect deviations, sediment accumulation, and potential defects early in the process. Whether for manual excavation or mechanized drilling, the TS-K100CW(P) offers a reliable solution for borehole size quality management and evaluation in various geological conditions.

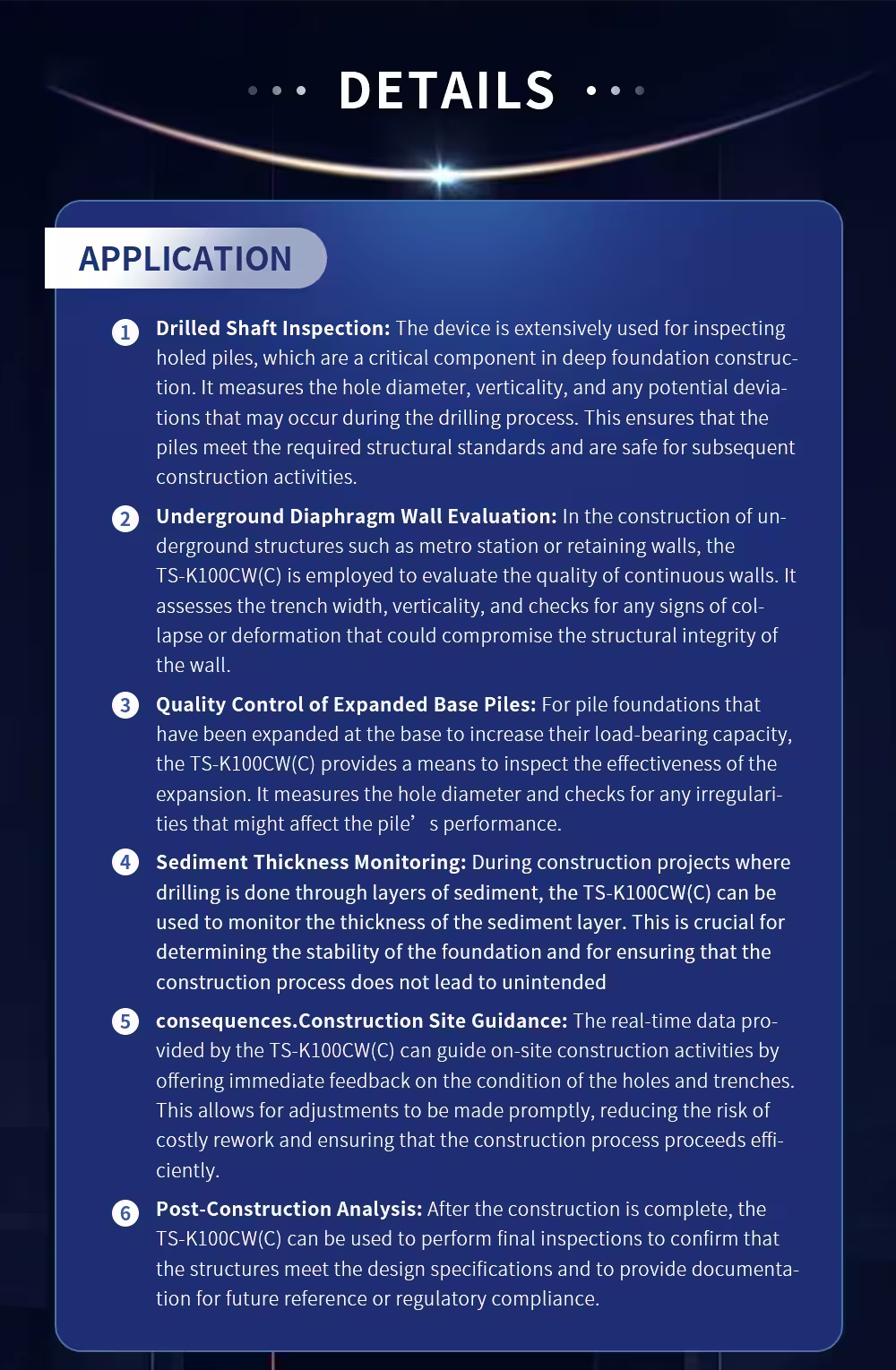

Applications :

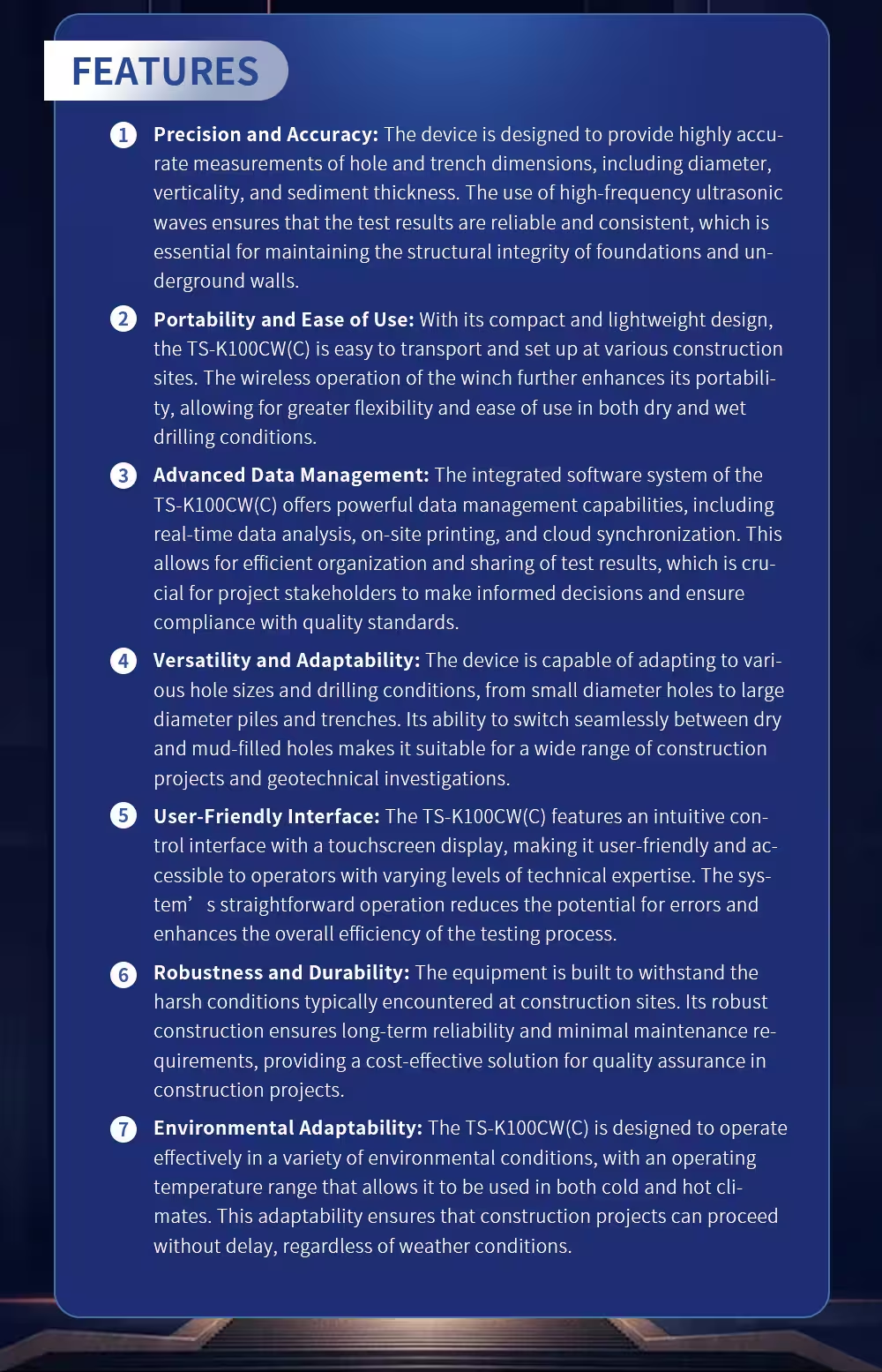

Features :