Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

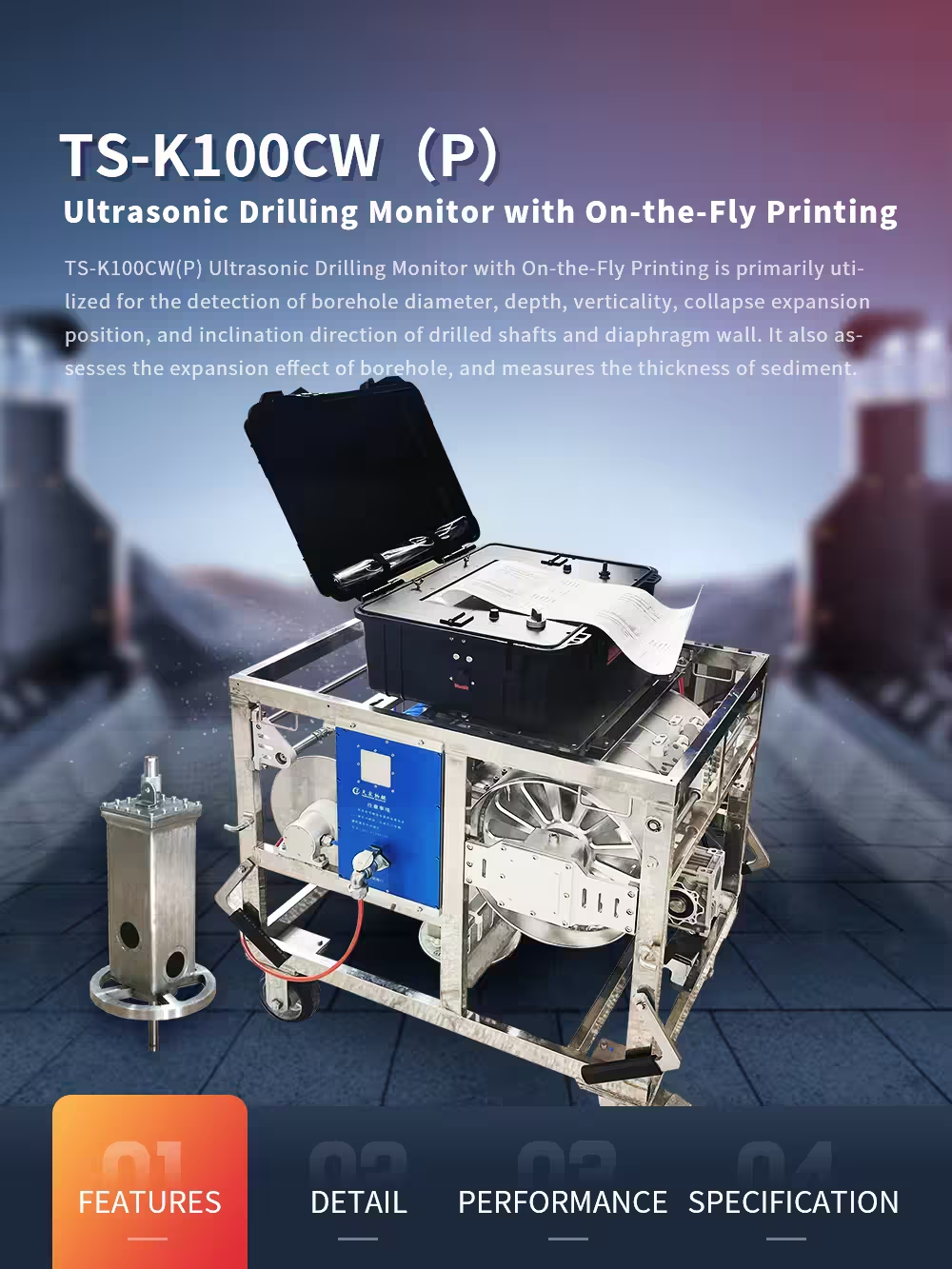

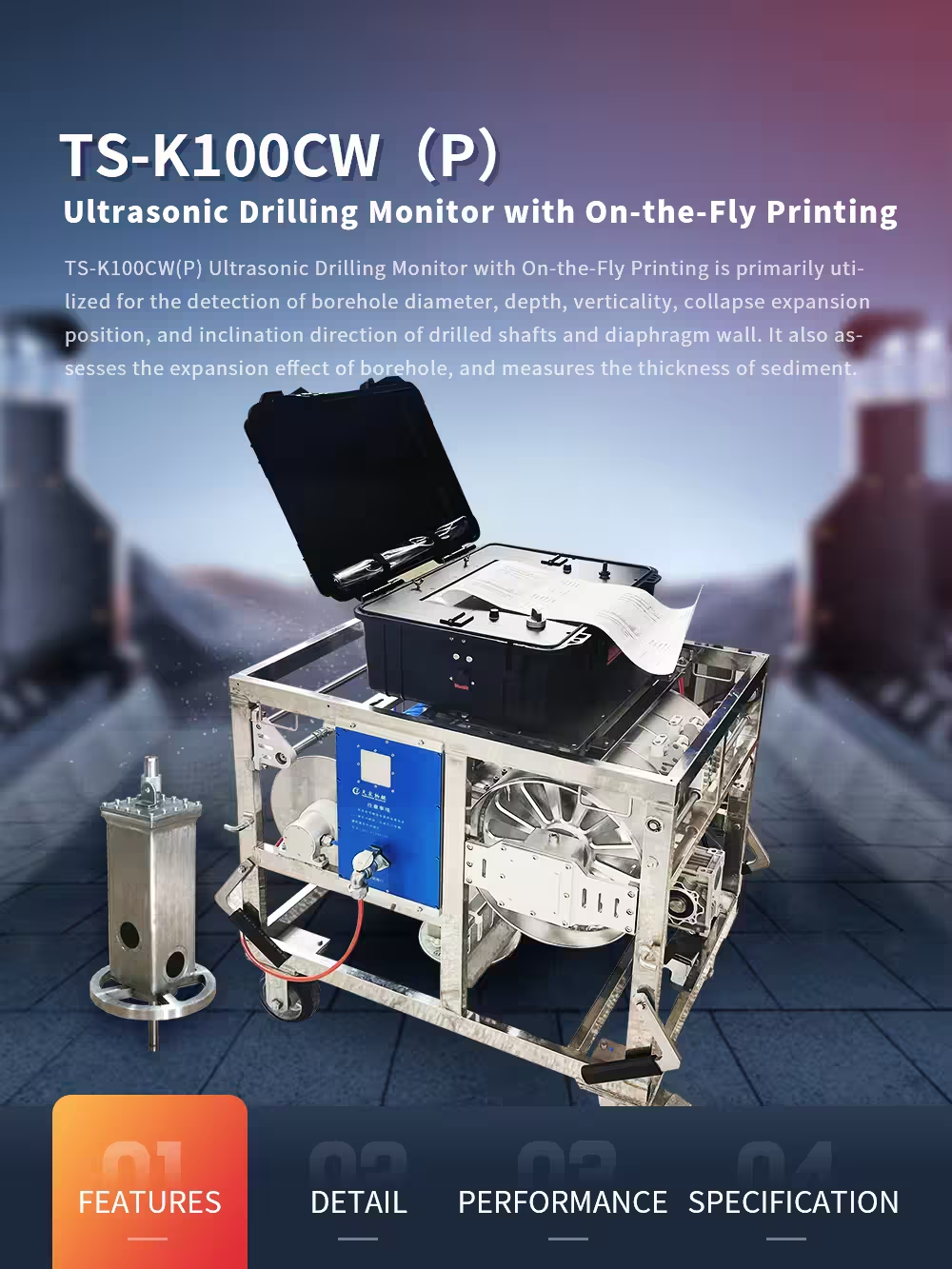

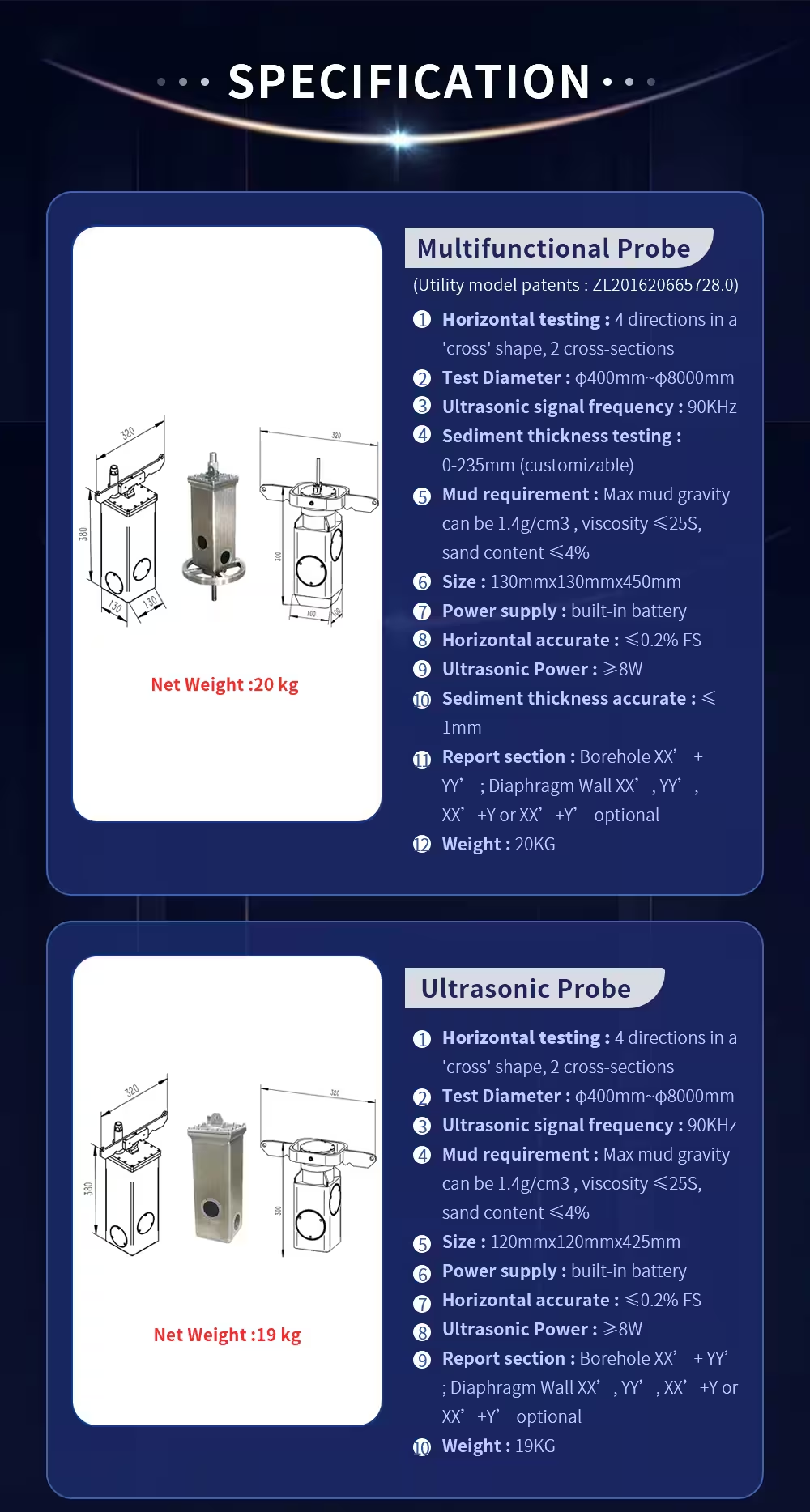

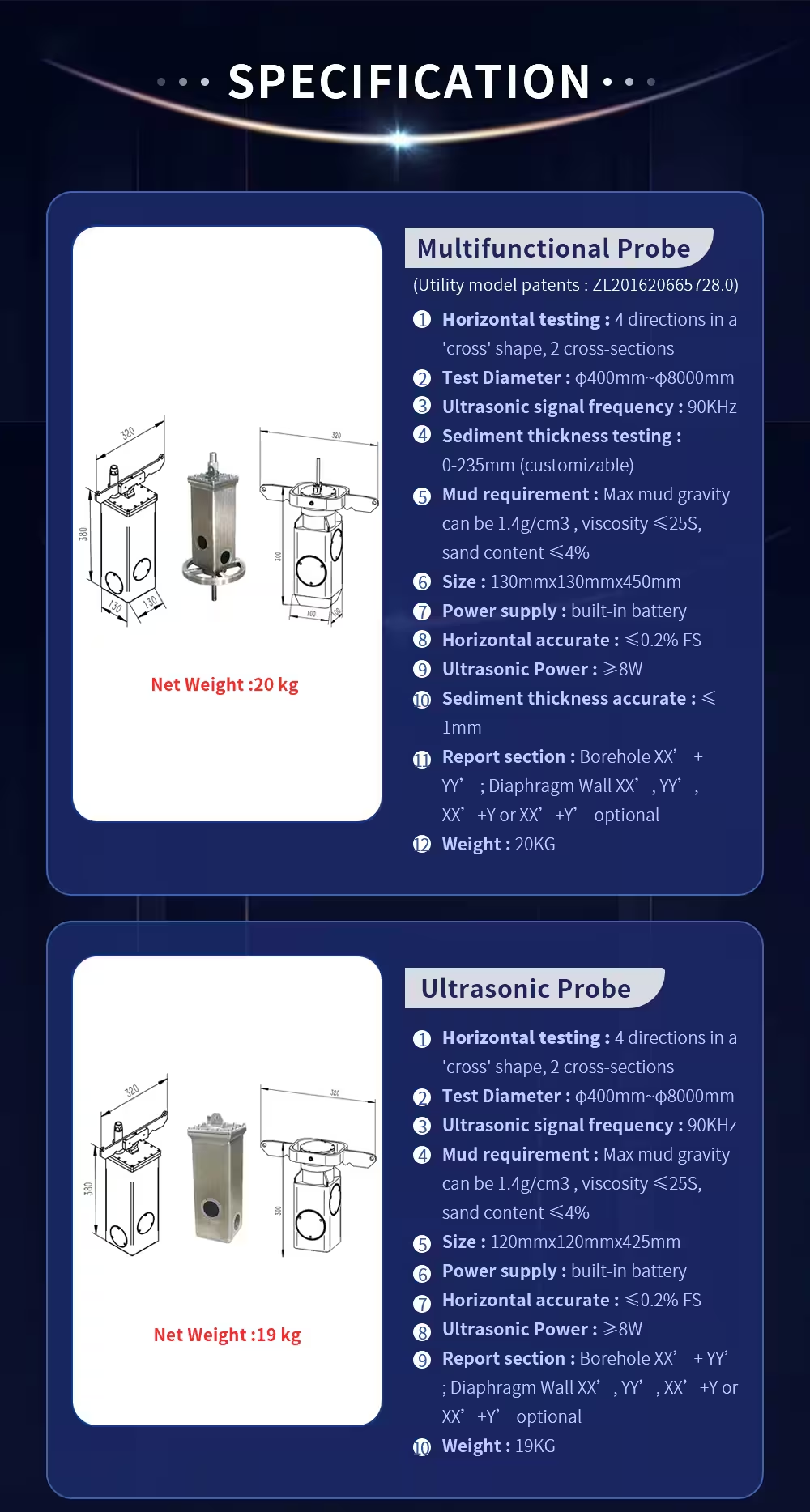

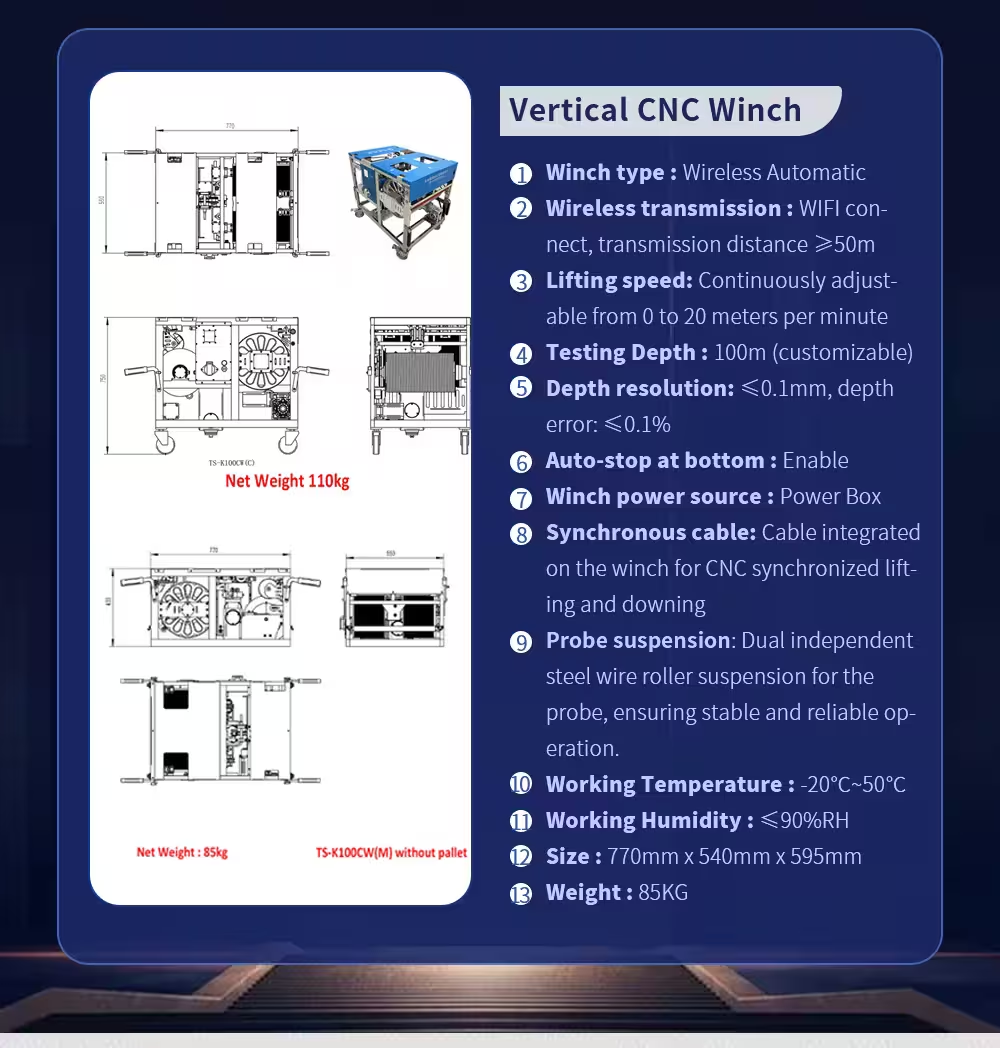

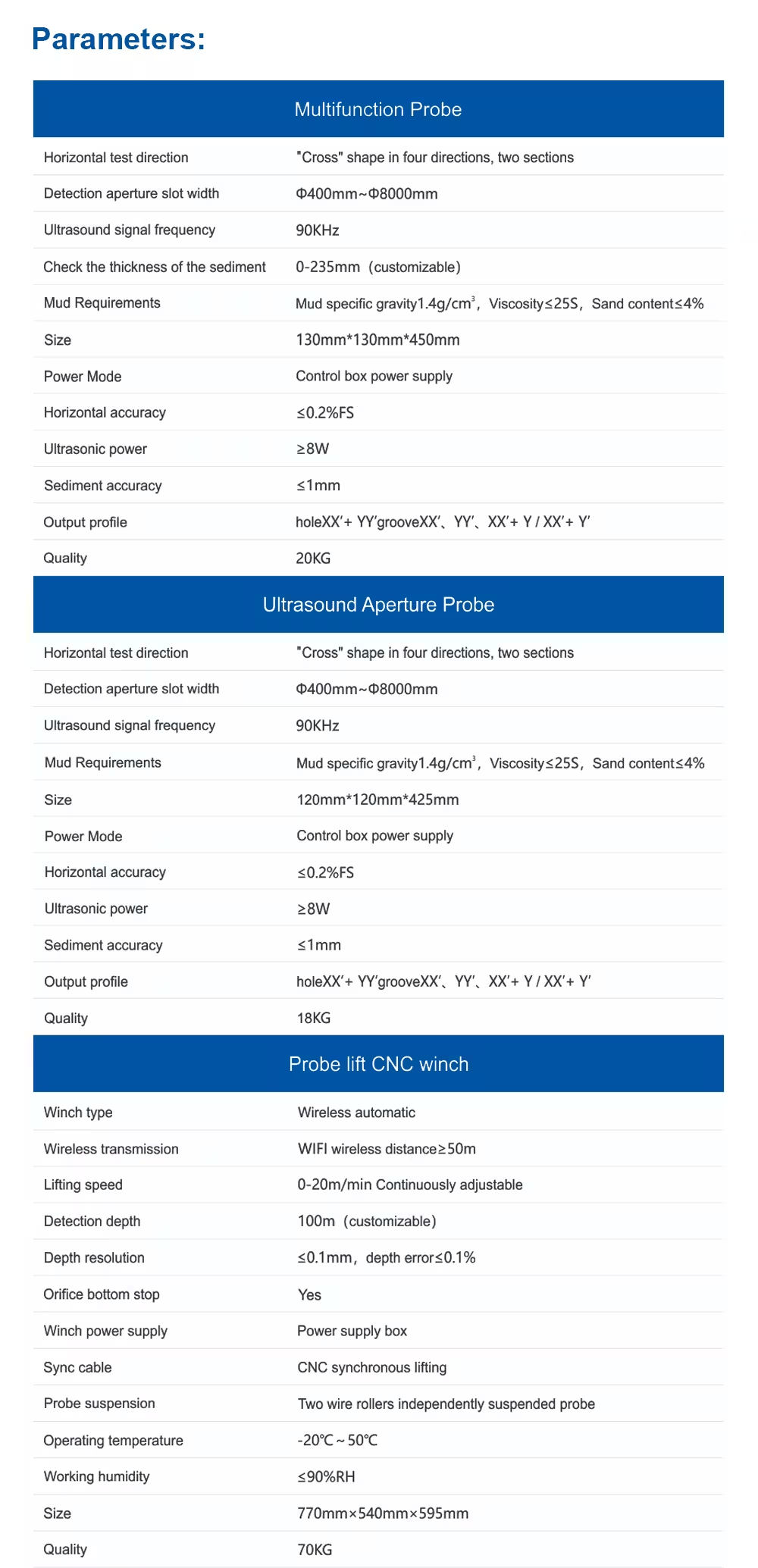

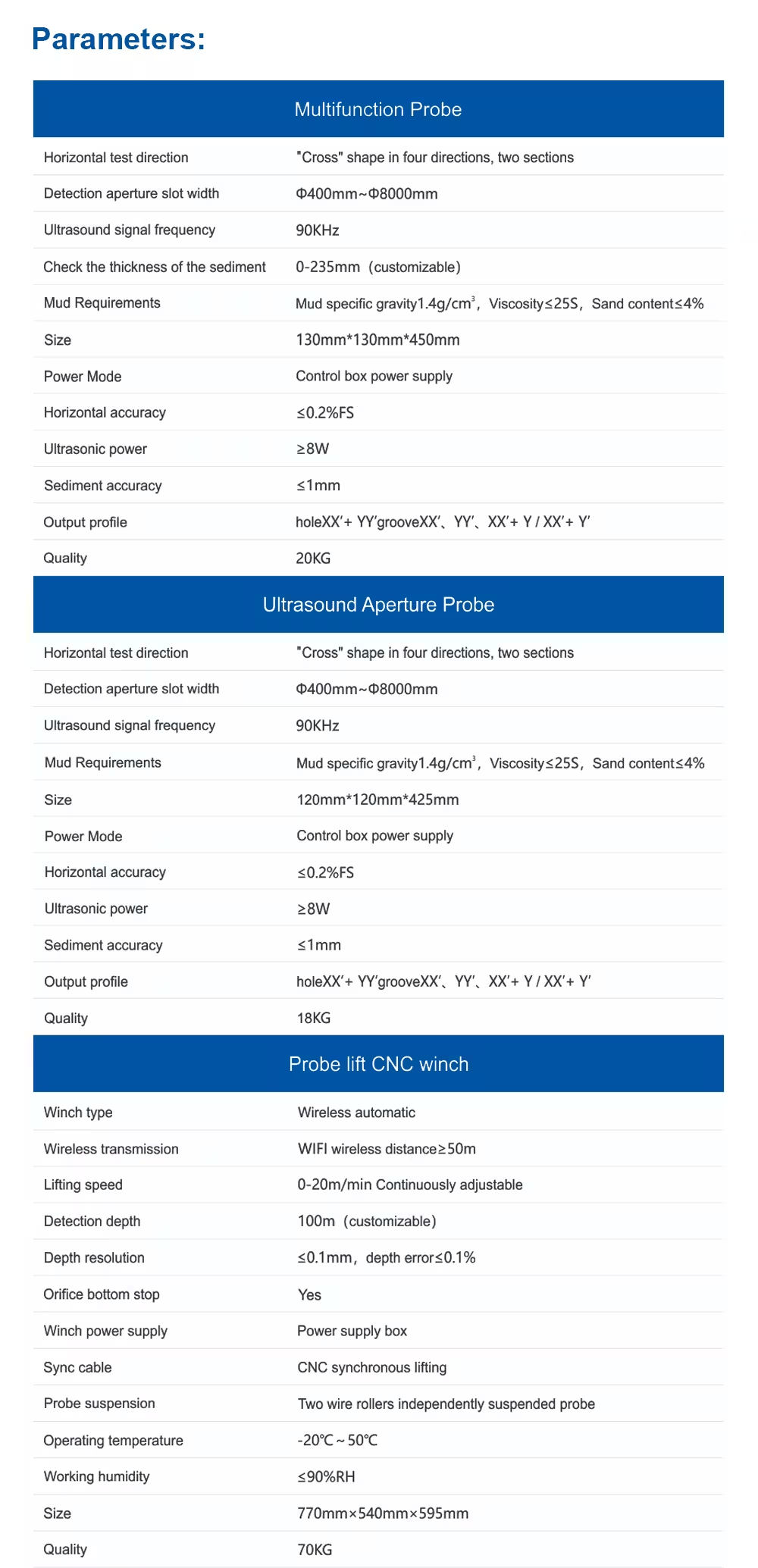

The TS-K100CW(P) Drilled Shaft Inspector is a state-of-the-art shaft quantitative inspection device designed to provide real-time evaluation of drilled shaft verticality, auger quality, and foundation integrity. Ensuring proper drilled shaft auger testing, monitoring, and inspection is critical for structural stability in deep foundation projects, including bridges, high-rise buildings, and infrastructure developments.

This system uses ultrasonic monitoring for drilled shafts to deliver precise shaft area profile evaluation, drilled shaft auger quality control, and verticality assessment. By detecting deviations, irregularities, and sediment accumulation, the TS-K100CW(P) enhances drilled shaft foundation construction inspection to meet engineering standards. Whether for drilled shaft auger assessment, shaft verticality evaluation, or quantitative drilled shaft analysis, this system provides automated testing, data collection, and cloud-based reporting to optimize efficiency and reduce risks

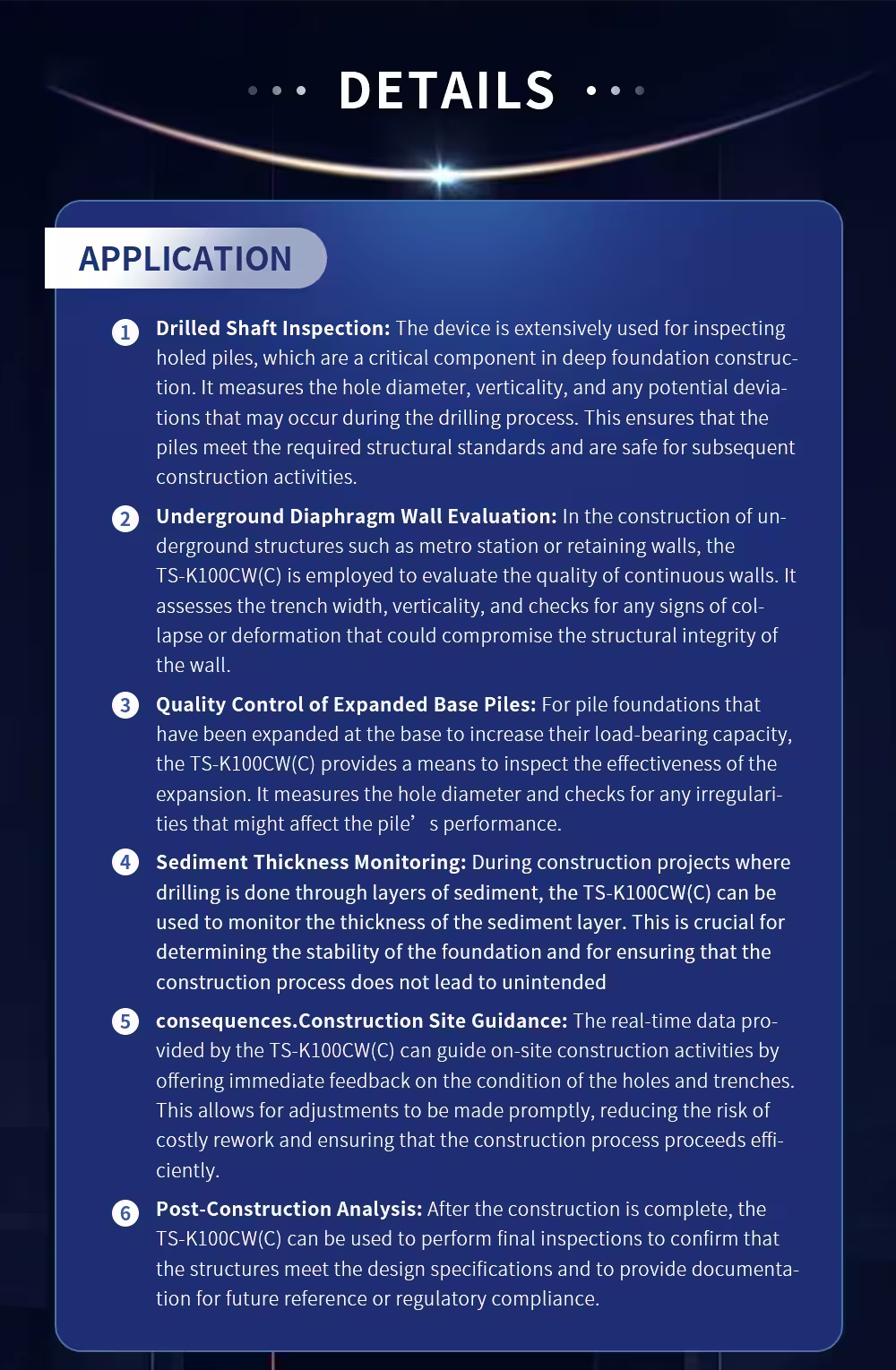

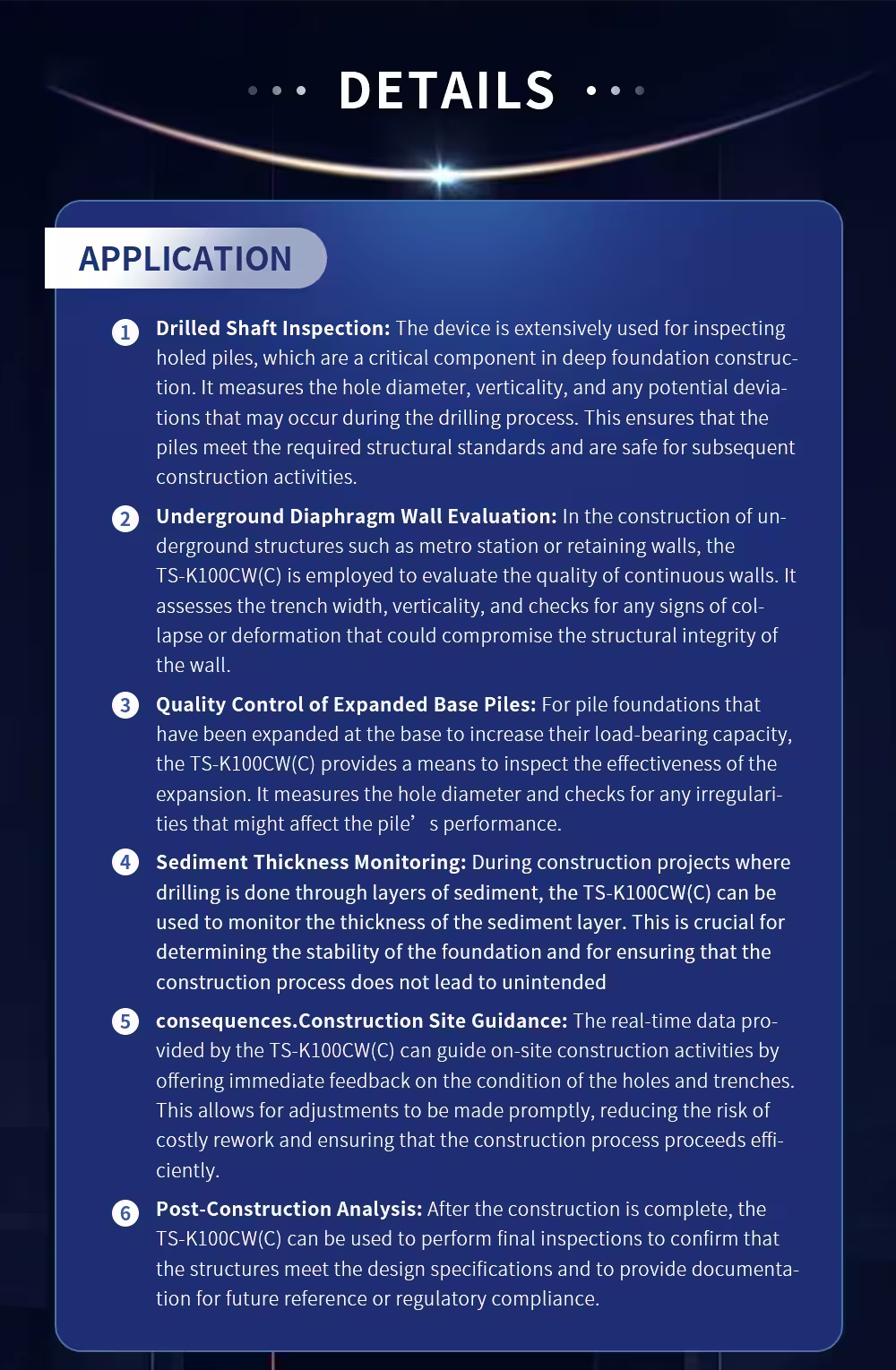

Applications :

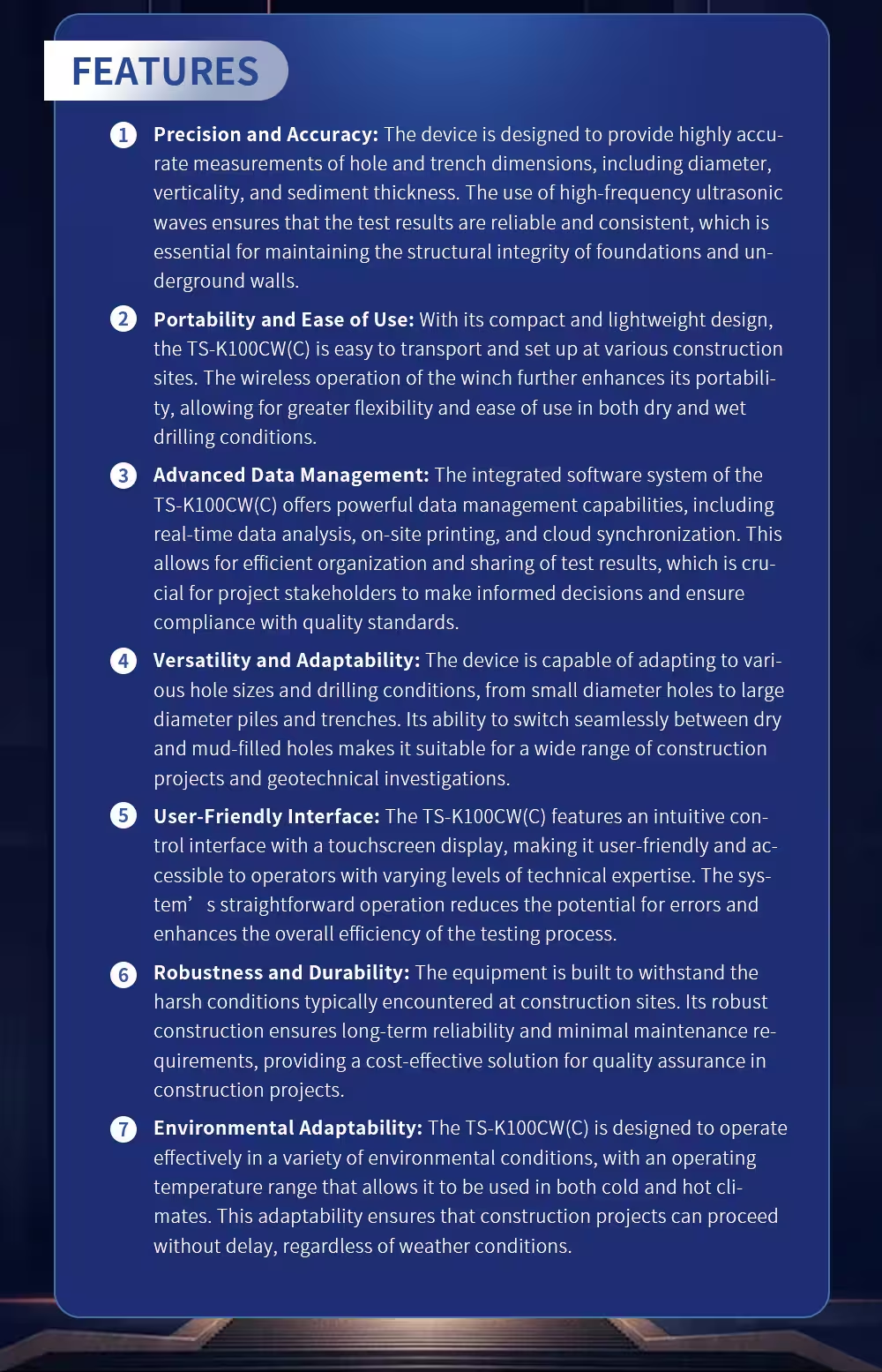

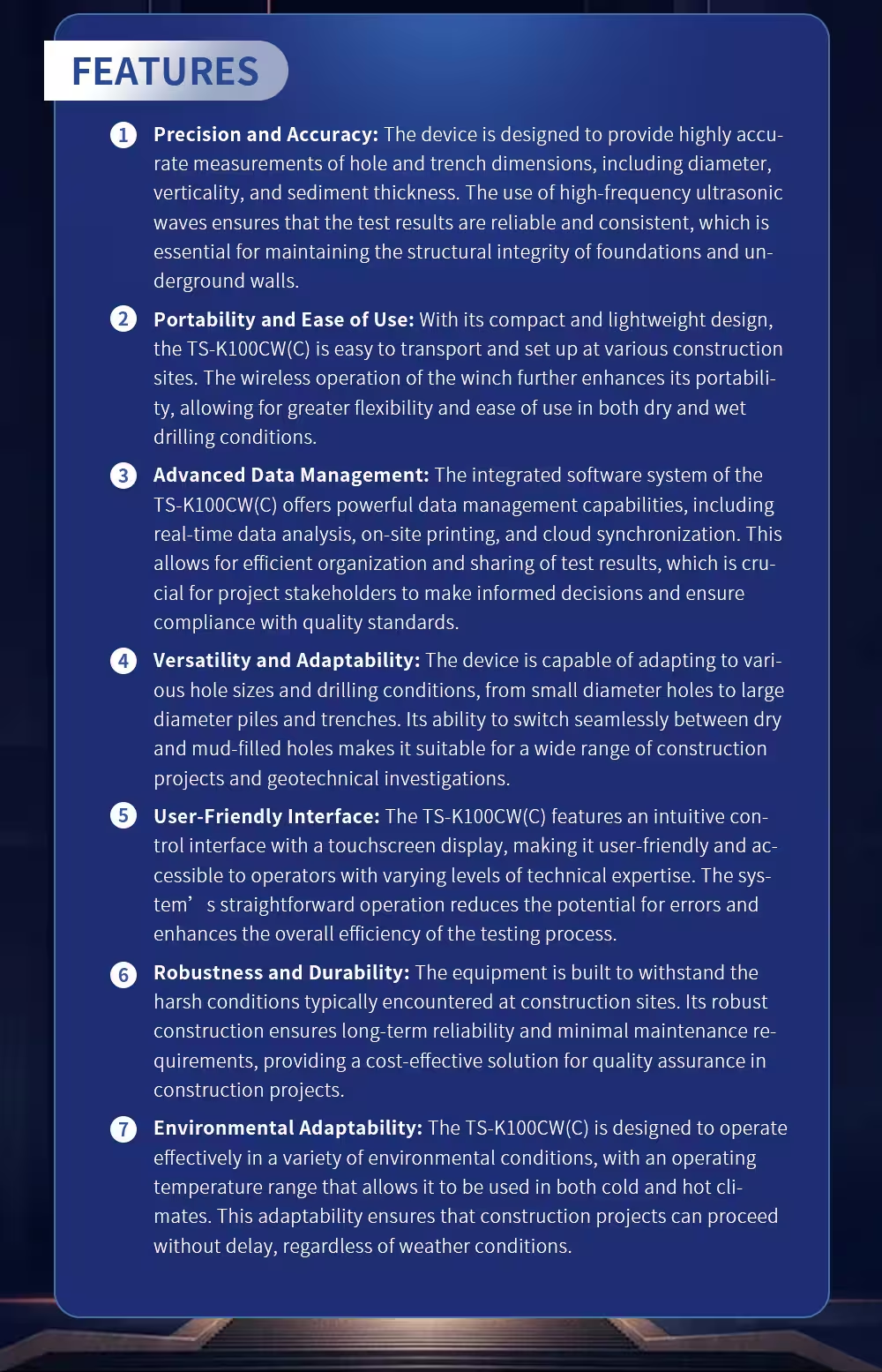

Features :