Tel.: +86-150 7112 0854 Email: abby@tensense-geotech.com

Revolutionizing Geotechnical Investigation: The Power of Optical Borehole Imaging System

An optical borehole imaging system is an advanced imaging tool used in geotechnical investigations to capture high-resolution, continuous 360° images and video recording of borehole walls. It employs a high-resolution camera and LED lighting to provide detailed visual data of geological features, such as fractures, bedding planes, dip angle, dip direction and rock fabric. This device is particularly valuable for structural analysis, as it delivers precise orientation and inclination data, allowing geologists and engineers to assess rock stability, lithology, and subsurface conditions accurately. Its non-destructive, in-situ imaging enhances understanding of the subsurface, supporting reliable decision-making in construction, mining, and groundwater studies.

The applications of optical borehole imaging systems are as diverse as they are impactful. From rock fracture analysis that reveals the intricate network of cracks and fissures under deep ground, to construction site evaluation that ensures the stability and safety of future structures, this technology is an indispensable ally in the geotechnical toolkit.

At the heart of this advanced technology lies a trio of key components:

- A high-resolution camera system that captures crystal-clear images and videos of borehole walls

- A sophisticated data acquisition module for seamless information gathering

- Advanced image processing software that turns raw data into actionable insights

Principal features

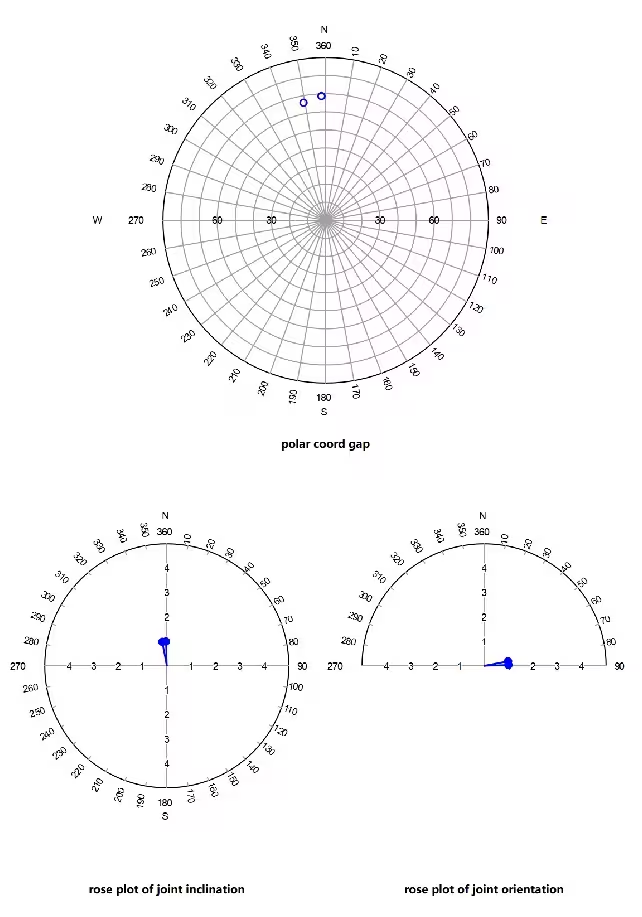

- Identifies and orientates (measures the dip angle and dip direction) of fractures, joints or other rock breaks.

- Measure the frequency of fractures/joints with depth

Applications

- Geotechnical site investigations where slope stability, rock support are key requirements.

- Tunnelling

- Structural geology.

- Casing integrity.

Technique

The optical borehole imaging system captures ultra-clear, 360° images of borehole walls in real-time, delivering unmatched detail for geotechnical assessments. Featuring a high-speed digital camera capturing maximum 60 frames per second, this device ensures every frame is precisely calibrated for true-to-life color accuracy. An innovative prism enables the camera to capture seamless 360° views of the entire borehole wall, while a powerful LED ring illuminates the borehole, enhancing visibility and image quality. Perfect for capturing structural data with pinpoint accuracy, the optical borehole imaging system supports confident, data-driven decisions for accurate structural and geological analysis.

Orientation of the image data

Orientation of the image (by orientation we mean a Magnetic North reference or a reference to the high side of the borehole) is achieved using a three axis magnetometer and a three axis accelerometer inside the probe.

Borehole and Probe Requirements

- Borehole Wall Visibility: The probe must capture clear images of the borehole wall sides for accurate analysis.

- Compatibility with Borehole Conditions: Suitable for both air-filled and clear fluid-filled boreholes.

- Centralized Positioning: The probe must be precisely centered within the borehole, achieved using tensense designed centralizer placed at the top of the probe.

- Borehole Diameter Range:

- Minimum diameter of 45mm.

- Maximum diameter up to 600mm, depending on viewing conditions.

Data acquisition settings

- High-Definition Imaging: Equipped with 700 TV Lines resolution and 0.01 Lux low-light capability, the camera captures a panoramic 360° view for detailed borehole wall imaging.

- User-Controlled Settings: Adjustable lighting, frame rate, movement speed, and exposure provide flexibility to suit diverse borehole conditions.

- Efficient Data Storage: Optical scanner files and video outputs are large but optimized for easy storage and management.

- Scanning Speed: Data transfer speeds determine the logging rate, typically up to 4 m/min during acquisition.

- Enhanced Transfer Rates: Newer imaging systems enable higher data transfer speeds, allowing for faster logging without sacrificing image resolution.

Data Processing

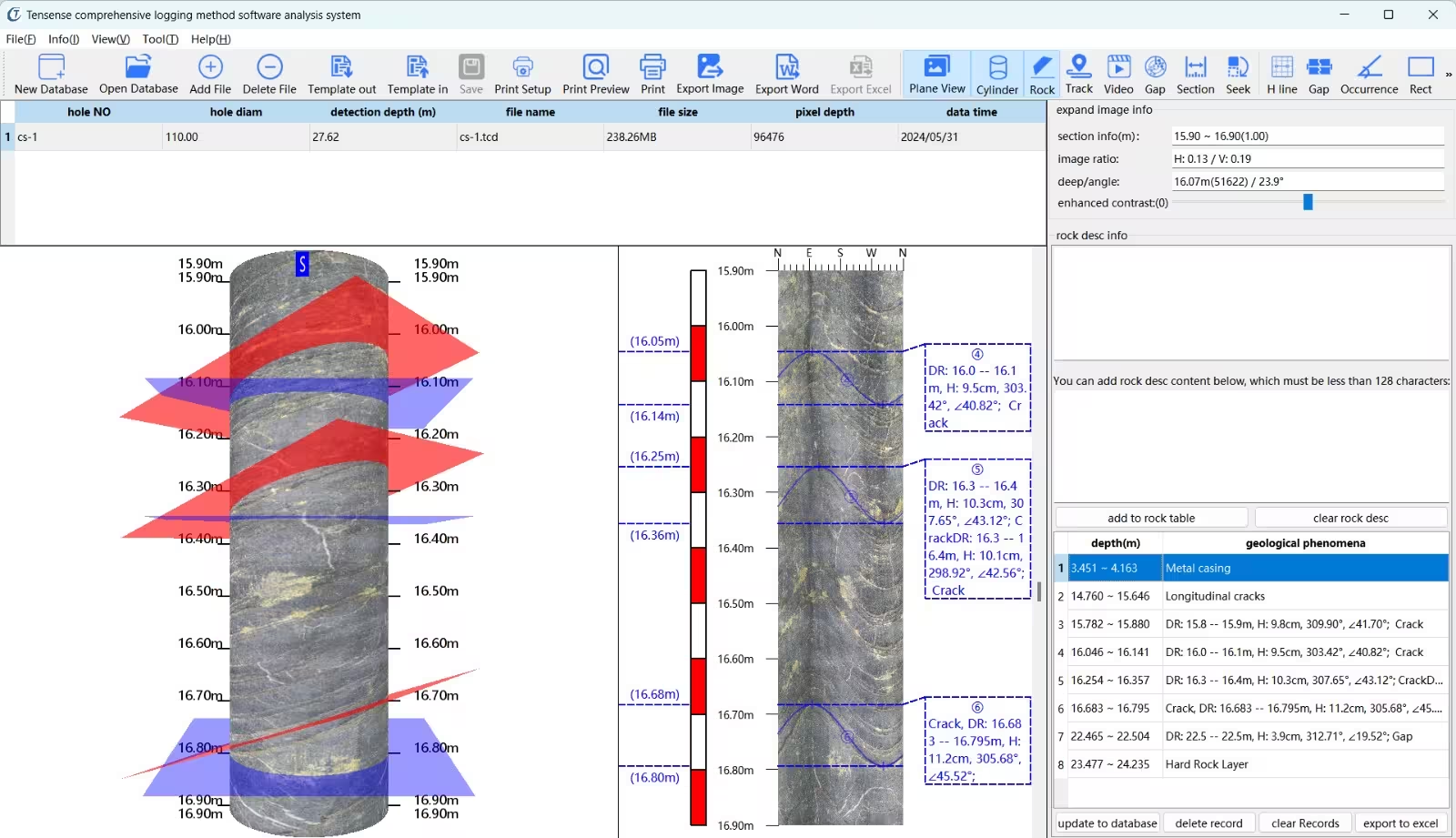

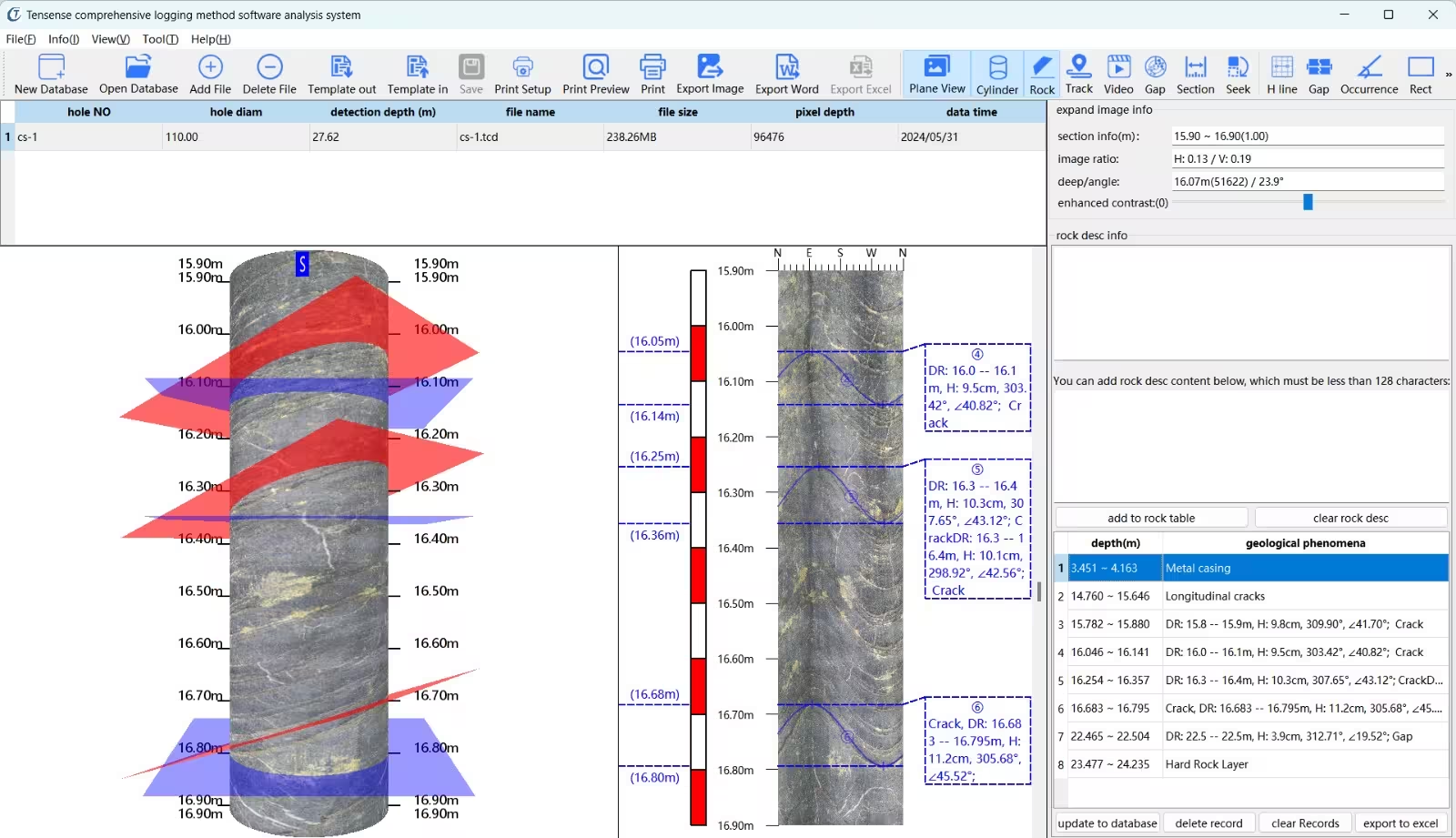

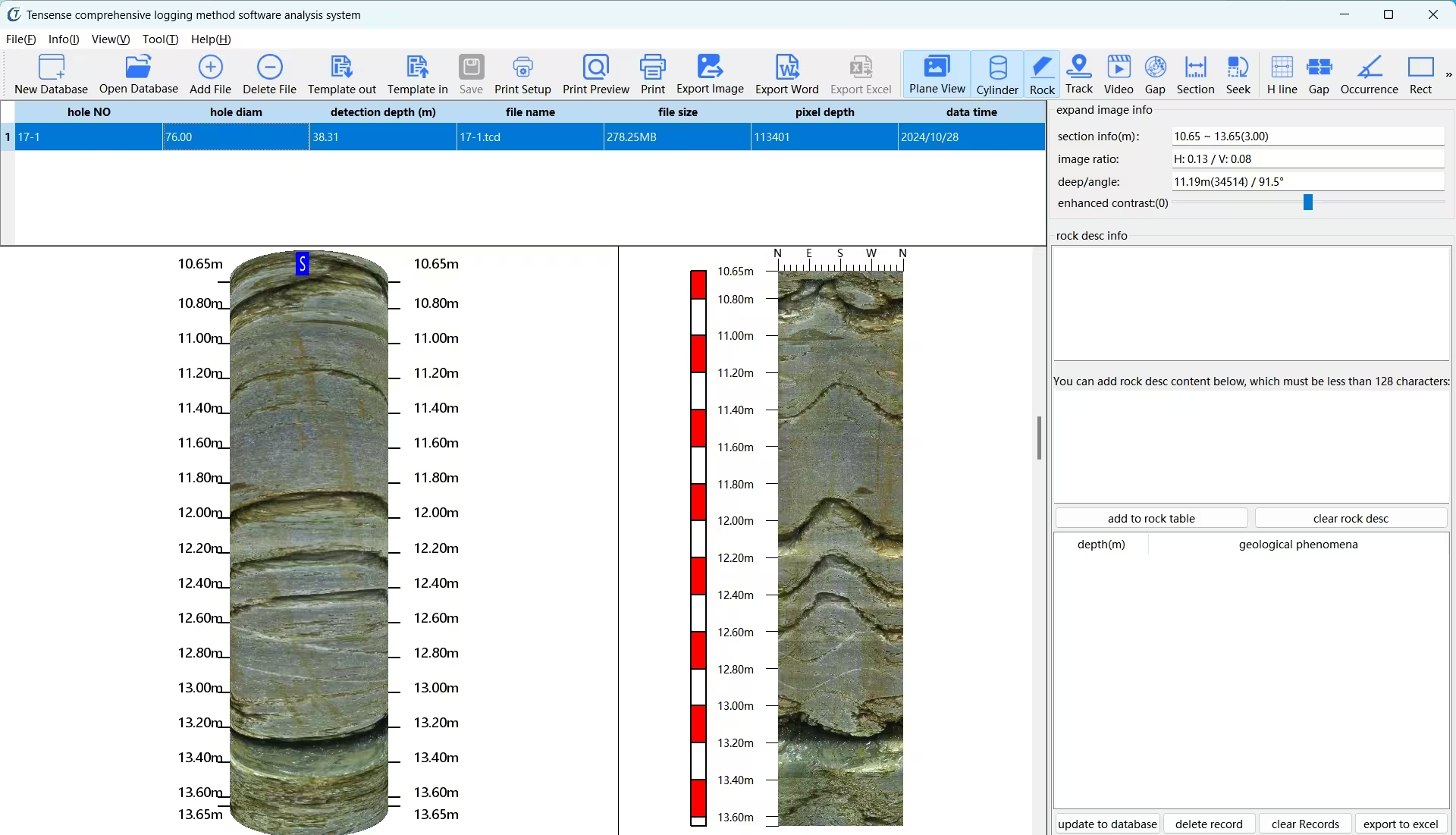

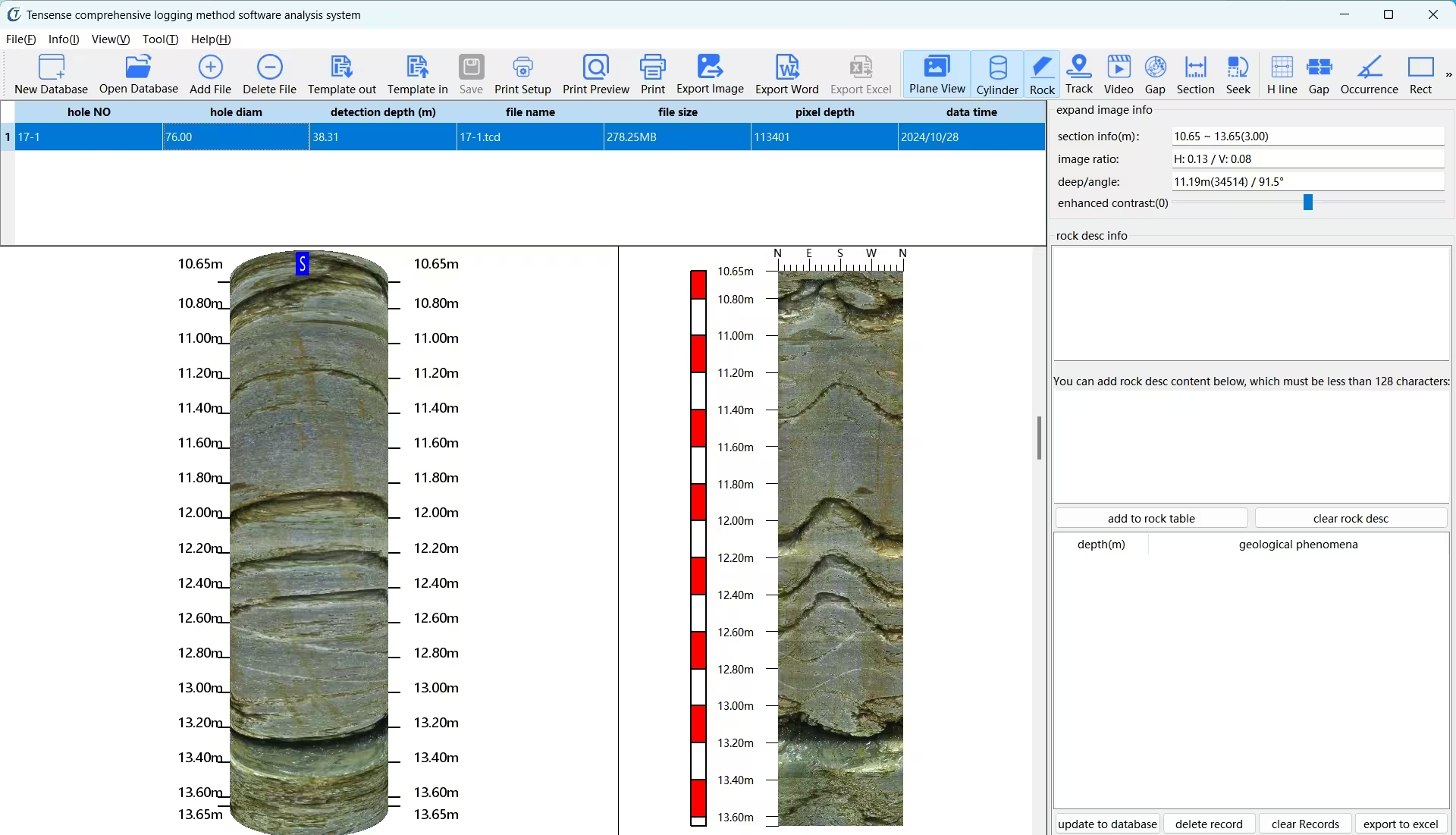

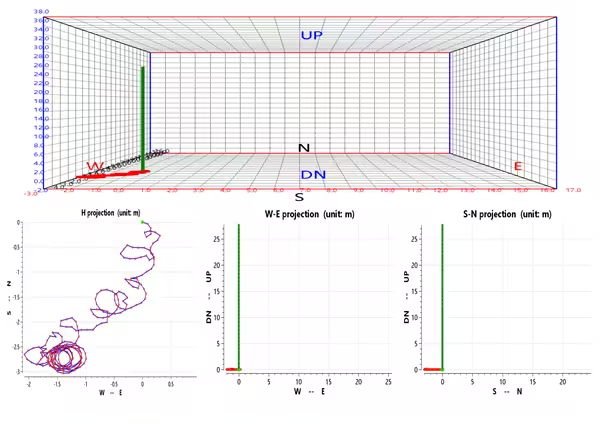

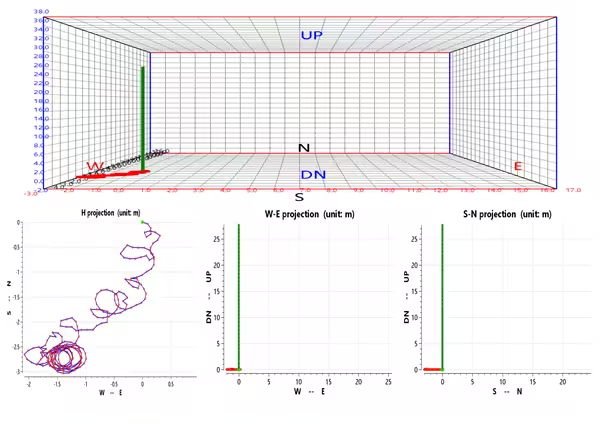

After data acquisition, borehole imaging technology enables precise identification of structures intersecting the borehole. Each structure’s dip angle and dip direction can be individually measured with high accuracy. The “unwrapped image” format, which displays the borehole wall as a continuous, flat image, allows dipping structures to appear as sine curves. From these curves, the dip angle and dip direction relative to the borehole can be calculated.

The final output report

Once image data is acquired, borehole imaging technology enables precise identification of structures intersecting the borehole, with individual measurements of dip angle and dip direction. Each structure is oriented, classified, and prepared for output as a detailed list and/or a stereographic projection. When combined with additional geophysical or geological borehole data, a 3D representation of the borehole is created, offering a comprehensive view of subsurface structures.

Contact Us

Address:

52# Liufang Road, East Lake High-tech Development Zone

Wuhan City, Hubei Province, China

Category

Inquiry

© 2026 All Rights Reserved.